Page 205 - Improving Machinery Reliability

P. 205

176 Improving Machinery Reliability

Pumps for Handling Entrained Gases

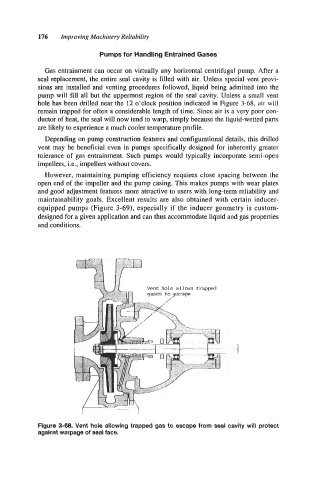

Gas entrainment can occur on virtually any horizontal centrifugal pump. After a

seal replacement, the entire seal cavity is filled with air. Unless special vent provi-

sions are installed and venting procedures followed, liquid being admitted into the

pump will fill all but the uppermost region of the seal cavity. Unless a small vent

hole has been drilled near the 12 o’clock position indicated in Figure 3-68, air will

remain trapped for often a considerable length of time. Since air is a very poor con-

ductor of heat, the seal will now tend to warp, simply because the liquid-wetted parts

are likely to experience a much cooler temperature profile.

Depending on pump construction features and configurational details, this drilled

vent may be beneficial even in pumps specifically designed for inherently greater

tolerance of gas entrainment. Such pumps would typically incorporate semi-open

impellers, i.e., impellers without covers.

However, maintaining pumping efficiency requires close spacing between the

open end of the impeller and the pump casing. This makes pumps with wear plates

and good adjustment features more attractive to users with long-term reliability and

maintainability goals. Excellent results are also obtained with certain inducer-

equipped pumps (Figure 3-69), especially if the inducer geometry is custom-

designed for a given application and can thus accommodate liquid and gas properties

and conditions.

Figure 3-68. Vent hole allowing trapped gas to escape from seal cavity will protect

against warpage of seal face.