Page 327 - Improving Machinery Reliability

P. 327

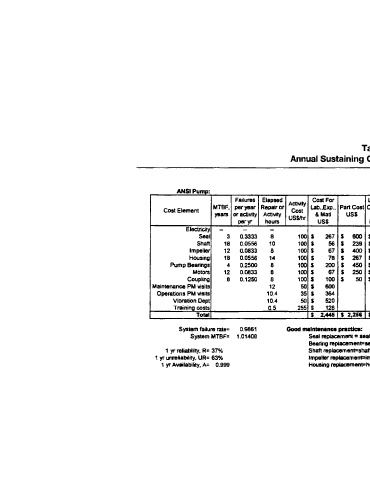

Table 5-12

Annual Sustaining Cost for Single ANSI Pump

-

Failurns Elapwd Cost For Logirticr Lo11 Gms! 1 US$ IC.stusI

cost MTBF. per year Repair or bb.,E.xp, Pan Cos cost US! Margin Total Cos1 Item Cost Logistics

yam oraclwb' AcbW US,,,r &Man USS -

uss

per

uss

-

- perv horn illcidant -

-

El-

Seal 3 03333 8 100 s 267 5 800 $50 S 10.667

Shafl 18 005s 10 100 S 56 S 239 S 25 s 2.222

tmpeller 12 0.0833 8 1W S 67 S 400 $38 5 2.667 seal coas s 1.5w s 75

Houung 18 005s 14 1w s 78 s 267 $64 S 3.111 S 3.519 Bearings cost= S300S 75

PumpBeanngs 4 025W 8 100 5 2w s 450 s38 s 8.m shan cost= S 2.5W S 3M)

Motors 12 00833 8 100 5 67 S 29 S 42 S 2.667 5 3.025 Impeller cos* s 3.000 s 300

Coupling 8 0 1250 8 1w s 100 s 50 538 s 4.m Pump housing= s 3.000 s 1,ooo

Mainbnanw PM nil& 12 50s 6w Motor cost= 5 3.000 t 500

Openbons PM nMs 10 4 35s 364 Coupling cost= S4M)S300

Vibrabon bpt 10 4 so s 520 os1 gross margin USmr = 5 4.000

--

Training costs 05 255 0 128 - 128 ower cost(USSl65~pyr)= S 165

-

TOhl S 2.446 S 2,266 s 293 S 33,333 I $ 16.600 S 64.127 Motor rize(hp)= 100

System farlure me= 0 9861 oood Nlnl.MW

System MTBF= 1 01408 Seal replacement = seals+baanngt

Bsanng mplscemmFssals+beanngs

1 yr reliablify. R= 37% SM mplsgment=shan+seala+bsanngs

1 yr unmhably. UR= 63% ImpeHer mplscama~im~ler*aaals+~a~gs

1 yr Availakllty. A= 0.999 HwMng rsplsasmant=hwamg+seals+beanngs