Page 370 - Improving Machinery Reliability

P. 370

336 Improving Machinery Reliability

piping. Nobody knows exactly what is going on inside the mixed layers of covering.

Due to “blindness anxiety,” many installers have resorted to an uninsulated arrange-

ment. This not only creates an occupational safety hazard, but can also lead to cracks

due to thermal shock from the environment andlor weather changes. In refineries,

fires around bellows-type expansion joints have often led to disaster.

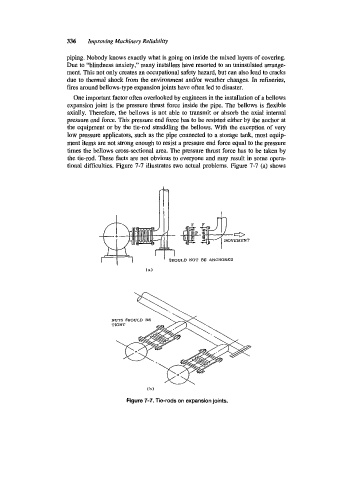

One important factor often overlooked by engineers in the installation of a bellows

expansion joint is the pressure thrust force inside the pipe. The bellows is flexible

axially. Therefore, the bellows is not able to transmit or absorb the axial internal

pressure end force. This pressure end force has to be resisted either by the anchor at

the equipment or by the tie-rod straddling the bellows. With the exception of very

low pressure applicators, such as the pipe connected to a storage tank, most equip-

ment items are not strong enough to resist a pressure end force equal to the pressure

times the bellows cross-sectional area. The pressure thrust force has to be taken by

the tie-rod. These facts are not obvious to everyone and may result in some opera-

tional difficulties. Figure 7-7 illustrates two actual problems. Figure 7-7 (a) shows

I

NUTS snoum BE

TIGHT

(b)

Figure 7-7. Tie-rods on expansion joints.