Page 367 - Improving Machinery Reliability

P. 367

Equipment Reliability Improvement Through Reduced Pipe Stress 333

Because of the elaborate design of the piping system attached to sensitive equip-

ment, engineers may sometimes get too trapped in the computer maze and overlook

engineering fundamentals. Typical examples that can cause unreliable operation are

discussed next.

Excessive Flexibility

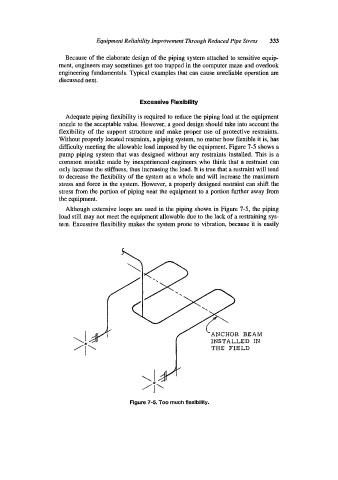

Adequate piping flexibility is required to reduce the piping load at the equipment

nozzle to the acceptable value. However, a good design should take into account the

flexibility of the support structure and make proper use of protective restraints.

Without properly located restraints, a piping system, no matter how flexible it is, has

difficulty meeting the allowable load imposed by the equipment. Figure 7-5 shows a

pump piping system that was designed without any restraints installed. This is a

common mistake made by inexperienced engineers who think that a restraint can

only increase the stiffness, thus increasing the load. It is true that a restraint will tend

to decrease the flexibility of the system as a whole and will increase the maximum

stress and force in the system. However, a properly designed restraint can shift the

stress from the portion of piping near the equipment to a portion further away from

the equipment.

Although extensive loops are used in the piping shown in Figure 7-5, the piping

load still may not meet the equipment allowable due to the lack of a restraining sys-

tem. Excessive flexibility makes the system prone to vibration, because it is easily

'* i f L~~~~~~ BEAM

INSTALLED IN

'I \ THE FIELD

Figure 7-5. Too much flexibility.