Page 364 - Improving Machinery Reliability

P. 364

330 Improving Machinery Reliability

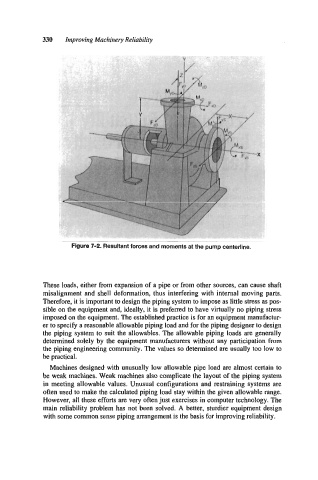

Figure 7-2. Resultant forces and moments at the pump centerline.

These loads, either from expansion of a pipe or from other sources, can cause shaft

misalignment and shell deformation, thus interfering with internal moving parts.

Therefore, it is important to design the piping system to impose as little stress as pos-

sible on the equipment and, ideally, it is prefened to have virtually no piping stress

imposed on the equipment. The established practice is for an equipment manufactur-

er to specify a reasonable allowable piping load and for the piping designer to design

the piping system to suit the allowables. The allowable piping loads are generally

determined solely by the equipment manufacturers without any participation from

the piping engineering community. The values so determined are usually too low to

be practical.

Machines designed with unusually low allowable pipe load are almost certain to

be weak machines. Weak machines also complicate the layout of the piping system

in meeting allowable values. Unusual configurations and restraining systems are

often used to make the calculated piping load stay within the given allowable range.

However, all these efforts are very often just exercises in computer technology. The

main reliability problem has not been solved. A better, sturdier equipment design

with some common sense piping arrangement is the basis for improving reliability.