Page 365 - Improving Machinery Reliability

P. 365

Equipment Reliability Improvement Through Reduced Pipe Stress 331

Allowable Load

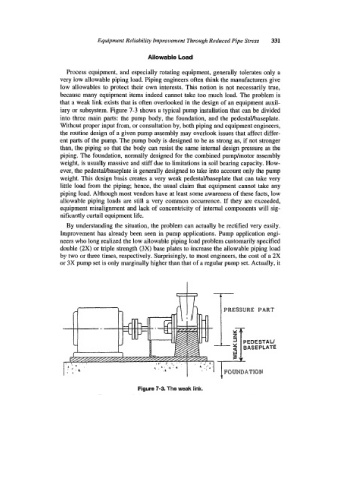

Process equipment, and especially rotating equipment, generally tolerates only a

very low allowable piping load. Piping engineers often think the manufacturers give

low allowables to protect their own interests. This notion is not necessarily true,

because many equipment items indeed cannot take too much load. The problem is

that a weak link exists that is often overlooked in the design of an equipment auxil-

iary or subsystem. Figure 7-3 shows a typical pump installation that can be divided

into three main parts: the pump body, the foundation, and the pedestalhaseplate.

Without proper input from, or consultation by, both piping and equipment engineers,

the routine design of a given pump assembly may overlook issues that affect differ-

ent parts of the pump. The pump body is designed to be as strong as, if not stronger

than, the piping so that the body can resist the same internal design pressure as the

piping. The foundation, normally designed for the combined pump/motor assembly

weight, is usually massive and stiff due to limitations in soil bearing capacity. How-

ever, the pedestalhaseplate is generally designed to take into account only the pump

weight. This design basis creates a very weak pedestalbaseplate that can take very

little load from the piping; hence, the usual claim that equipment cannot take any

piping load. Although most vendors have at least some awareness of these facts, low

allowable piping loads are still a very common occurrence. If they are exceeded,

equipment misalignment and lack of concentricity of internal components will sig-

nificantly curtail equipment life.

By understanding the situation, the problem can actually be rectified very easily.

Improvement has already been seen in pump applications. Pump application engi-

neers who long realized the low allowable piping load problem customarily specified

double (2X) or triple strength (3X) base plates to increase the allowable piping load

by two or three times, respectively. Surprisingly, to most engineers, the cost of a 2X

or 3X pump set is only marginally higher than that of a regular pump set. Actually, it

PRESSURE PART

FOUNDATION

Figure 7-3. The weak link.