Page 98 - Improving Machinery Reliability

P. 98

70 Improving Machinery Reliability

secondary sealing. Seals with spring loaded running faces are forced to use dynamic

means of secondary sealing which could, in some instances, be more prone to fail-

ure. This potential problem can be overcome by selecting "stationary" and/or gas

seal designs. In a stationary seal, the spring-loaded face is not rotating.

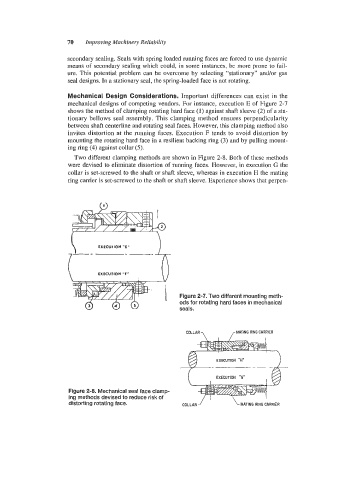

Mechanical Design Considerations. Important differences can exist in the

mechanical designs of competing vendors. For instance, execution E of Figure 2-7

shows the method of clamping rotating hard face (1) against shaft sleeve (2) of a sta-

tionary bellows seal assembly. This clamping method ensures perpendicularity

between shaft centerline and rotating seal faces. However, this clamping method also

invites distortion at the running faces. Execution F tends to avoid distortion by

mounting the rotating hard face in a resilient backing ring (3) and by pulling mount-

ing ring (4) against collar (5).

Two different clamping methods are shown in Figure 2-8. Both of these methods

were devised to eliminate distortion of running faces. However, in execution G the

collar is set-screwed to the shaft or shaft sleeve, whereas in execution H the mating

ring carrier is set-screwed to the shaft or shaft sleeve. Experience shows that perpen-

EXECUTION "E"

--_

EXECUrlON "F"

I Figure 2-7. Two different mounting meth-

ods for rotating hard faces in mechanical

seals.

MATING RING CARRIER

Figure 2-8. Mechanical seal face clamp-

ing methods devised to reduce risk of

distorting rotating face. MATING RING CARRIER