Page 210 - Industrial Cutting of Textile Materials

P. 210

Fusing of cut textile components 197

2 3 5

1 7

4 6

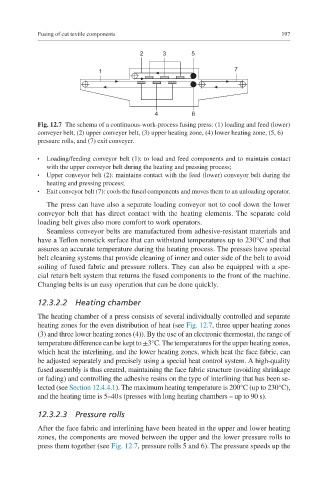

Fig. 12.7 The schema of a continuous-work-process fusing press: (1) loading and feed (lower)

conveyer belt, (2) upper conveyer belt, (3) upper heating zone, (4) lower heating zone, (5, 6)

pressure rolls, and (7) exit conveyer.

Loading/feeding conveyor belt (1): to load and feed components and to maintain contact

●

with the upper conveyor belt during the heating and pressing process;

Upper conveyor belt (2): maintains contact with the feed (lower) conveyor belt during the

●

heating and pressing process;

Exit conveyor belt (7): cools the fused components and moves them to an unloading operator.

●

The press can have also a separate loading conveyor not to cool down the lower

conveyor belt that has direct contact with the heating elements. The separate cold

loading belt gives also more comfort to work operators.

Seamless conveyor belts are manufactured from adhesive-resistant materials and

have a Teflon nonstick surface that can withstand temperatures up to 230°C and that

assures an accurate temperature during the heating process. The presses have special

belt cleaning systems that provide cleaning of inner and outer side of the belt to avoid

soiling of fused fabric and pressure rollers. They can also be equipped with a spe-

cial return belt system that returns the fused components to the front of the machine.

Changing belts is an easy operation that can be done quickly.

12.3.2.2 Heating chamber

The heating chamber of a press consists of several individually controlled and separate

heating zones for the even distribution of heat (see Fig. 12.7, three upper heating zones

(3) and three lower heating zones (4)). By the use of an electronic thermostat, the range of

temperature difference can be kept to ±3°C. The temperatures for the upper heating zones,

which heat the interlining, and the lower heating zones, which heat the face fabric, can

be adjusted separately and precisely using a special heat control system. A high-quality

fused assembly is thus created, maintaining the face fabric structure (avoiding shrinkage

or fading) and controlling the adhesive resins on the type of interlining that has been se-

lected (see Section 12.4.4.1). The maximum heating temperature is 200°C (up to 230°C),

and the heating time is 5–40 s (presses with long heating chambers – up to 90 s).

12.3.2.3 Pressure rolls

After the face fabric and interlining have been heated in the upper and lower heating

zones, the components are moved between the upper and the lower pressure rolls to

press them together (see Fig. 12.7, pressure rolls 5 and 6). The pressure speeds up the