Page 46 - Industrial Cutting of Textile Materials

P. 46

Principles and methods of textile spreading 33

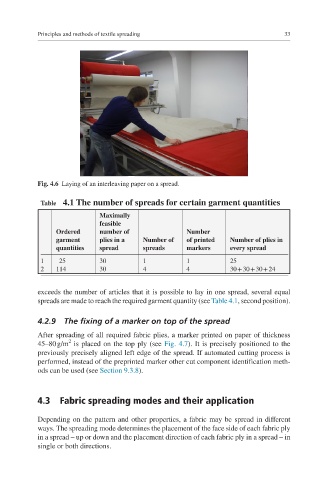

Fig. 4.6 Laying of an interleaving paper on a spread.

Table 4.1 The number of spreads for certain garment quantities

Maximally

feasible

Ordered number of Number

garment plies in a Number of of printed Number of plies in

quantities spread spreads markers every spread

1 25 30 1 1 25

2 114 30 4 4 30 + 30 + 30 + 24

exceeds the number of articles that it is possible to lay in one spread, several equal

spreads are made to reach the required garment quantity (see Table 4.1, second position).

4.2.9 The fixing of a marker on top of the spread

After spreading of all required fabric plies, a marker printed on paper of thickness

2

45–80 g/m is placed on the top ply (see Fig. 4.7). It is precisely positioned to the

previously precisely aligned left edge of the spread. If automated cutting process is

performed, instead of the preprinted marker other cut component identification meth-

ods can be used (see Section 9.3.8).

4.3 Fabric spreading modes and their application

Depending on the pattern and other properties, a fabric may be spread in different

ways. The spreading mode determines the placement of the face side of each fabric ply

in a spread – up or down and the placement direction of each fabric ply in a spread – in

single or both directions.