Page 187 - Industrial Power Engineering and Applications Handbook

P. 187

Special-purpose motors 7/167

Loads and installations that cannot use a standard motor

due to their constructional needs, operational demands,

special functions, unfavourable location of installation,

hazardous items of process, etc. require a special motor,

either in mechanical construction or in performance

characteristics or both. During performance, such loads

may require a prolonged starting time, a high starting

torque, smoother acceleration, frequent cold or hot starts,

stops and reversals etc. For all such applications,

meticulous selection of the motor is essential, which should

meet all the load requirements without excessive cost

and yet achieve a higher efficiency and conserve energy

in addition to fulfilling environmental needs. Special

features of a few such applications are discussed below.

7.1 Textile motors

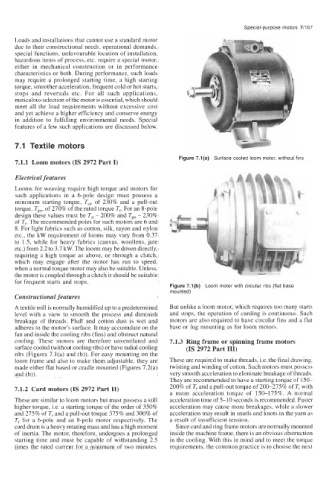

Figure 7.l(a) Surface cooled loom motor, without fins

7.1.1 Loom motors (IS 2972 Part I)

Electrical features

Looms for weaving require high torque and motors for

such applications in a 6-pole design must possess a

minimum starting torque, T,,, of 230% and a pull-out

torque, Tpo, of 270% of the rated torque TI. For an 8-pole

design these values must be Tst - 200% and Tpo - 230%

of T,. The recommended poles for such motors are 6 and

8. For light fabrics such as cotton, silk, rayon and nylon

etc., the kW requirement of looms may vary from 0.37

to 1.5, while for heavy fabrics (canvas, woollens, jute

etc.) from 2.2 to 3.7 kW. The looms may be driven directly,

requiring a high torque as above, or through a clutch,

which may engage after the motor has run to speed,

when a normal torque motor may also be suitable. Unless,

the motor is coupled through a clutch it should be suitable

for frequent starts and stops.

Figure 7.l(b) Loom motor with circular ribs (flat base

mounted)

Constructional features

A textile mill is normally humidified up to a predetermined But unlike a loom motor, which requires too many starts

level with a view to smooth the process and diminish and stops, the operation of carding is continuous. Such

breakage of threads. Fluff and cotton dust is wet and motors are also required to have circular fins and a flat

adheres to the motor’s surface. It may accumulate on the base or lug mounting as for loom motors.

fan and inside the cooling ribs (fins) and obstruct natural

cooling. These motors are therefore unventilated and 7.1.3 Ring frame or spinning frame motors

surface cooled (without cooling ribs) or have radial cooling (IS 2972 Part 111)

ribs (Figures 7.l(a) and (b)). For easy mounting on the

loom frame and also to make them adjustable, they are These are required to make threads, i.e. the final drawing,

made either flat based or cradle mounted (Figures 7.2(a) twisting and winding of cotton. Such motors must possess

and (b)). very smooth acceleration to eliminate breakage of threads.

They are recommended to have a starting torque of 150-

7.1.2 Card motors (IS 2972 Part 11) 200% of TI and a pull-out torque of 200-275% of TI with

a mean acceleration torque of 150-175%. A normal

These are similar to loom motors but must possess a still acceleration time of 5-10 seconds is recommended. Faster

higher torque, Le. a starting torque of the order of 350% acceleration may cause more breakages, while a slower

and 275% of TI and a pull-out torque 375% and 300% of acceleration may result in snarls and knots in the yarn as

TI for a 6-pole and an 8-pole motor respectively. The a result of insufficient tension.

card drum is a heavy rotating mass and has a high moment Since card and ring frame motors are normally mounted

of inertia. The motor, therefore, undergoes a prolonged inside the machine frame, there is an obvious obstruction

starting time and must be capable of withstanding 2.5 in the cooling. With this in mind and to meet the torque

times the rated current for a minimum of two minutes. requirements, the common practice is to choose the next