Page 212 - Industrial Power Engineering and Applications Handbook

P. 212

7/192 Industrial Power Engineering and Applications Handbook

stops, heating and cooling curves of the motor should be

‘2=[m] 600 x8

available and the manufacturer may be consulted.

The above exercise is only for a general guidance. In

= 32 seconds such cases, the manufacturer should be consulted who

To determine the number of equally spread starts and may offer a better and more economical design.

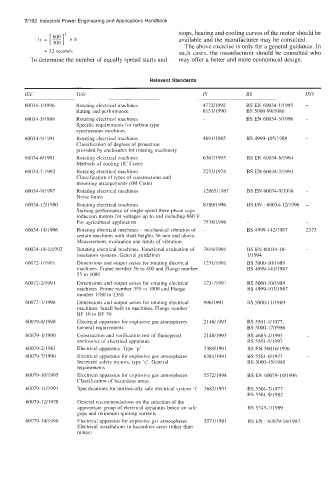

Relevant Standards

IEC Title IS BS IS0

60034-1/1996 Rotating electrical machines 472211 992 BS EN 60034-1/1995 -

Rating and performance 8 15 1/1990 BS 5000-99/1986

60034-3/1988 Rotating electrical machines ~ BS EN 60034-3/1996 -

Specific requirements for turbine type

synchronous machines

60034-5/1991 Rotating electrical machines 469 1/1985 BS 4999-105/1988 -

Classification of degrees of protection

provided by enclosures for rotating machinery

60034-6/1991 Rotating electrical machincs 6362/1995 BS EN 60034-6/1994

Methods of cooling (IC Code)

60034-7-1992 Rotating electrical machines 2253/1974 BS EN 60034-7/1993

Classification of types of constructions and

mounting arrangements (IM Code)

60034-9/1997 Rotating electrical machines 12065/1987 BS EN 60034-9/1998 -

Noise limits

60034- 12/1980 Rotating electrical machines 8789/ 1996 BS EN : 60034-12/1996 -

Starting performance of single-speed three-phase cage

induction motors for voltages up to and including 660 V

For agricultural application 7538/1996 - -

60034-14/1996 Rotating electrical machines - mechanical vibration of - BS 4999-l42/1987 2373

certain machines with shaft heights 56 mm and above.

Measurement, evaluation and limits of vibration

60034-18- 1/1992 Rotating electrical machines. Functional evaluation of 78 I6/199l BS EN 60034-18-

insulation systems. General guidelines 1/1994

60072- 1/199 I Dimensions and output series for rotating electrical 123 1/199 1 BS 5000-10/1989

machines. Frame number 56 to 400 and Flange number BS 4999-141/1987

55 to 1080

60072-2/1991 Dimensions and output series for rotating electrical I23 1/1991 BS 5000-10/1989

machines. Frame number 355 to 1000 and Flange BS 4999-103/1987

number 1 180 to 2360

60072-3/ 1994 Dimensions and output series for rotating electrical 996/199 1 BS 5000-1 1/1989

machines. Small built-in machines. Flange number

BF 10 to BF 50

60079-0/1998 Electrical apparatus for explosive gas atmospheres 2 148/1993 BS 5501-1/1977,

General requirements BS 5000-17/1986

60079-l/1990 Construction and verification test of flameproof 2 148/1993 BS 4683-2/1993

enclosures of electrical apparatus BS 5501-5/1997

60079-2/1983 Electrical apparatus. Type ‘p’ 7389/199 1 BS EN 50016/1996

60079-7/ 1990 Electrical apparatus for explosive gas atmospheres 638 1/199 1 BS 5501-6/1977

Increased safety motors, type ‘e’. General BS 5000-15/1985

requirements

60079-10/1995 Electrical apparatus for explosive gas atmospheres 5572/1994

Classification of hazardous areas

60079- 1 I/ 199 1 Specifications for intrinsically safe electrical system ’i’ 3682/1991 BS 5501-7/1977

BS 5501-9/1982

60079- 12/1978 General recommendations on the selection of the

appropriate group of electrical apparatus based on safe BS 5345-1/1989

gaps and minimum igniting currents

60079- 14/1996 Electrical apparatus for explosive gas atmospheres 5571/1991 BS EN : 60079-14/1997

Electrical installations in hazardous areas (other than

mines)