Page 271 - Industrial Power Engineering and Applications Handbook

P. 271

11/250 Industrial Power Engineering and Applications Handbook

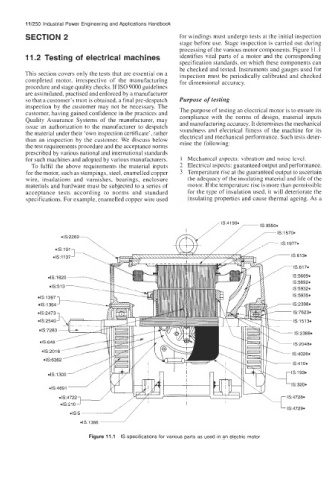

SECTION 2 for windings must undergo tests at the initial inspection

stage before use. Stage inspection is carried out during

processing of the various motor components. Figure I 1.1

11.2 Testing of electrical machines identifies vital parts of a motor and the corresponding

specification standards, on which these components can

be checked and tested. Instruments and gauges used for

This section covers only the tests that are essential on a inspection must be periodically calibrated and checked

completed motor, irrespective of the manufacturing for dimensional accuracy.

procedure and stage quality checks. If IS0 9000 guidelines

are assimilated, practised and enforced by a manufacturer

so that a customer’s trust is obtained, a final pre-despatch Purpose of testing

inspection by the customer may not be necessary. The The purpose of testing an electrical motor is to ensure its

customer, having gained confidence in the practices and compliance with the norms of design, material inputs

Quality Assurance Systems of the manufacturer, may and manufacturing accuracy. It determines the mechanical

issue an authorization to the manufacturer to despatch soundness and electrical fitness of the machine for its

the material under their ‘own inspection certificate’, rather electrical and mechanical performance. Such tests deter-

than an inspection by the customer. We discuss below mine the following:

the test requirements procedure and the acceptance norms

prescribed by various national and international standards

for such machines and adopted by various manufacturers. 1 Mechanical aspects: vibration and noisc level.

To fulfil the above requirements the material inputs 2 Electrical aspects: guaranteed output and performance.

for the motor, such as stampings, steel, enamelled copper 3 Temperature rise at the guaranteed output to ascertain

wire, insulations and varnishes, bearings, enclosure the adequacy of the insulating material and life of the

materials and hardware must be subjected to a series of motor. If the temperature rise is more than permissible

acceptance tests according to norms and standard for the type of insulation used, it will deteriorate the

specifications. For example, enamelled copper wire used insulating properties and cause thermal ageing. As a

*15:2269 -,

Figure 11.1 IS specifications for various parts as used in an electric motor