Page 559 - Industrial Power Engineering and Applications Handbook

P. 559

Captive (emergency) power generation 16/533

I

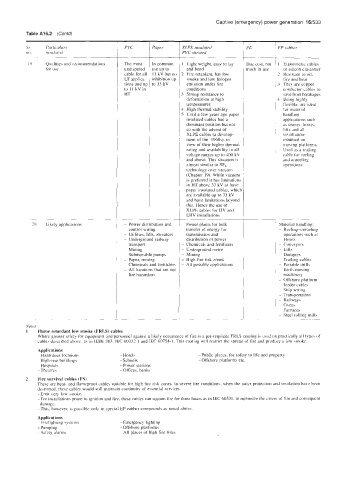

Pupper XLPE insuluted PE EP richhei

PVC shented

________

In common

use up to

cable for all 11 kV but no 2 Fire retardant, has low 2 Resistant to oil,

LT applica inhibition up smoke and low halogen fire and heat

tions and up to 33 kV emission under fire ~ 3 They are copper

to 11 kV in conditions conductor cables to

HT 3 Strong resistance to save from breakages

deformation at high 4 Being highly

temperatures flexible. are ideal

1 High thermal stability for material

5 Until a few years ago paper handling

insulated cables had a applications such

dominant position but not as cranes. hoists,

so with the advent of ' I lifts and all

XLPE cables (a develop- In~Vd~latloIl\

ment of the 1960s). in mounted on

view of their higher thermal moving platform\.

rating and availability in all Uqed as a trailing

voltage ranges up to 400 kV ~ cable for reeling

and above. This situation is and unreeling

almost similar to SF,, operations

technology over vacuum

(Chapter 19). While vacuum

is preferred it has limitations

in HT above 33 kV as havc

paper insulated cables, which

are available up to 33 kV

and have limitations beyond

this. Hence the use of

XLPE cables for HV and

~- _ _ ~ - ~- EHV installations

20 Likely applications Power distribution and ~ Power plants for hulk Mziaidc

control wiring transfer of energy for - Reeling-unreeling

Utilities, lifts, elevators transmission and operations such as

Underground railway distribution of power - Hoists

transport - Chemicals and fertilizers - Conveyors

Mining - Underground metro - Lifts

Submersible pumps ~ - Mining ~ - Dumpers

Paper, mining - High fire risk zones - Trailing cables

Chemicals and fertilizer? - All possible applications - Portable drill\

All locations that are not i - Earth-moving

I - Offshore platform

fire hazardous machinery

feeder cables

' - Ship wiring

- Transportation

- Railways

- Ovens

- Furnaces

I - Steel rolling mills

~.

NOIt,.\

I Flame retardant low smoke (FRLS) cables

Where greater safety for equipment and personnel against a likely occurrence of fire is a pre-requisite FRLS coating is used on practically all types of

cable?, described abovc. as in IEEE 383, IEC 60332 I and IEC 60754-1. This coating will restrict the spread of fire and produce a low smoke.

Applications

- Hazardous location. -Hotels -Public places, for safety to life and property

-High rise huildingr -Schools -Offshore platforms etc

- Ho\pitals -Power stations

~ Thearc\ -Office\, banks

2 Fire survival cables (FS)

These are heat- and flameproof cables suitable for high f-ire risk zones. In severe fire conditions, when the outer protection and insulation have been

destroyed, these cables would still maintain continuity of essential services.

-Emit vrry low smoke.

-For installations prone to ignition and fire, these cables can sustain fire for three hours as in IEC 60331, to minimize the extent offire and consequent

damage.

-This. however. I\ pos\ible only in special EP rubber compounds as noted above.

Applications

- Firefighting sy\terns -Emergency lighting

-Pumping - Offshore platforms

-Safety alarm\ -All places of high fire risks