Page 960 - Industrial Power Engineering and Applications Handbook

P. 960

29/91 0 Industrial Power Engineering and Applications Handbook

joint to suit the site requirement and help to connect

the two ends.

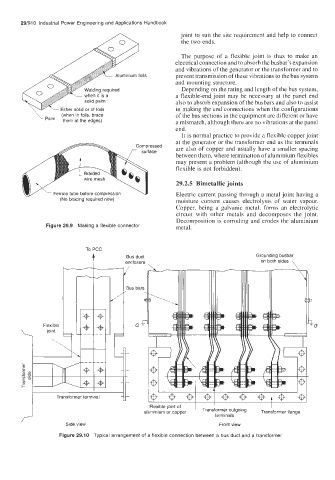

The purpose of a flexible joint is thus to make an

electrical connection and to absorb the busbar's expansion

and vibrations of the generator or the transformer and to

Aluminium foils prevent transmission of these vibrations to the bus system

and mounting structure.

Welding required Depending on the rating and length of the bus system,

a flexible-end joint may be necessary at the panel end

also to absorb expansion of the busbars and also to assist

Either solid or of foils in making the end connections when the configurations

(when in foils, brace of the bus sections in the equipment are different or have

Palm them at the edges) a mismatch, although there are no vibrations at the panel

end.

It is normal practice to provide a flexible copper joint

at the generator or the transformer end as the terminals

are also of copper and usually have a smaller spacing

between them, where termination of aluminium flexibles

may present a problem (although the use of aluminium

flexible is not forbidden).

29.2.5 Bimetallic joints

Ferrule tube before compression Electric current passing through a metal joint having a

(No bracing required now) moisture content causes electrolysis of water vapour.

Copper, being a galvanic metal, forms an electrolytic

circuit with other metals and decomposes the joint.

Decomposition is corroding and erodes the aluminium

Figure 29.9 Making a flexible connector metal.

To PCC

Bus duct

enclosure , Grounding busbar \

on both sides

Flexible

- -

LW +

*

m

t-

Transformer terminal - .-

i

2 Side view Front view

Figure 29.10 Typical arrangement of a flexible connection between a bus duct and a transformer