Page 956 - Industrial Power Engineering and Applications Handbook

P. 956

29/906 Industrial Power Engineering and Applications Handbook

Bolt head

Plain washer ,-20 + 3-, Shank

Min. 2 threads

to protrude

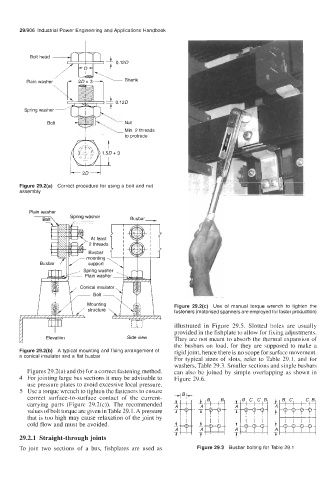

Figure 29.2(a) Correct procedure for using a bolt and nut

assembly

Plain washer

Busbar-

Figure 29.2(c) Use of manual torque wrench to tighten the

fasteners (motorised spanners are employed for faster production)

illustrated in Figure 29.5. Slotted holes are usually

provided in the fishplate to allow for fixing adjustments.

Elevation Side view They are not meant to absorb the thermal expansion of

the busbars on load, for they are supposed to make a

Figure 29.2(b) A typical mounting and fixing arrangement of rigid joint, hence there is no scope for surface movement.

a conical insulator and a flat busbar

For typical sizes of slots, refer to Table 29.1, and for

washers, Table 29.3. Smaller sections and single busbars

Figures 29.2(a) and (b) for a correct fastening method. can also be joined by simple overlapping as shown in

4 For jointing large bus sections it may be advisable to Figure 29.6.

use pressure plates to avoid excessive local pressure.

5 Use a torque wrench to tighten the fasteners to ensure

correct surface-to-surface contact of the current-

carrying parts (Figure 29.2(c)). The recommended

values of bolt torque are given in Table 29.1. A pressure

that is too high may cause relaxation of the joint by

cold flow and must be avoided. i

A

7

29.2.1 Straight-through joints

To join two sections of a bus, fishplates are used as Figure 29.3 Busbar bolting for Table 29.1