Page 972 - Industrial Power Engineering and Applications Handbook

P. 972

30/920 Industrial Power Engineering and Applications Handbook

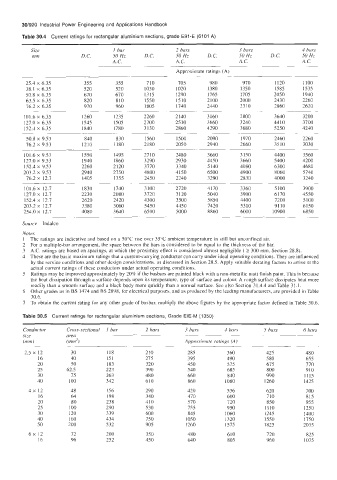

Table 30.4 Current ratings for rectangular aluminium sections, grade E91-E (6101 A)

Size I bur 2 burs 3 burs 4 burs

mm D. C. 50 Hz D. C. 50 Hz D. C. 50 Hz D. C. 50 Hz

A. C. A. C. A.C. A.C.

Approximate ratings (A)

25.4 x 6.35 355 355 710 705 980 970 1120 1100

38.1 x 6.35 520 520 1030 I020 1380 1350 1585 1535

50.8 x 6.35 670 670 1315 1290 1765 1705 2050 1940

63.5 x 6.35 820 810 1550 1510 2100 2000 2430 2260

76.2 x 6.3.5 970 960 1805 I740 2440 2310 2860 2620

~~________ .~

~~ ~~ ~~ ~ ~

101.6 x 6.35 1260 1235 2260 2140 3060 2800 3640 3200

127.0 x 6.35 1545 1 505 2700 2510 3660 3240 4410 3700

152.4 x 6.35 1840 1780 3130 2860 4290 3680 5250 4240

~. - ~~ . ~~~~._________________

~~

50.8 x 9.53 840 830 I560 1 500 2090 1970 2460 2260

76.2 x 9.53 1210 1180 2180 2050 2940 2660 35 10 3030

~ ..

101.6 x 9.53 1550 1495 2710 2480 3660 3150 4400 3560

127.0 x 9.53 1940 I860 3290 2930 4450 3660 5400 4200

152.4 x 9.53 2260 2120 3770 3340 5 I40 4080 6300 4680

203.2 x 9.53 2940 2750 4800 4150 6500 4900 8060 5740

76.2 x 12.7 I405 1355 2450 2240 3290 2830 4000 3240

~

101.6 x 12.7 1830 1740 3 100 2720 4170 3360 5 100 3900

127.0 x 12.7 2230 2080 3720 3120 5040 3900 6170 4550

152.4 x 12.7 2620 2420 4300 3500 5850 4400 7200 5100

203.2 x 12.7 3380 3060 5450 4450 7420 5300 91 10 6150

254.0 x 12.7 4080 3640 6500 5000 8860 6000 10900 6850

-

~ ~~ ~~ ______ ~ ~ . ~ . _ _ _ _ _ _ _ ~ ~ ~ ~

Source Indalco

Notes

1 The ratings are indicative and based on a 50°C rise over 35°C ambient temperature in still hut unconfined air.

2 For a multiple-bar arrangement, the space between the bars is considered to be equal to the thickness of the bar.

3 A.C. ratings are based on spacings, at which the proximity effect is considered almost negligible ( 2 300 mm, Section 28.8).

4 These are the basic maximum ratings that a current-carrying conductor can carry under ideal operating conditions. They are influenced

by the service conditions and other design considerations, as discussed in Section 28.5. Apply suitable derating factors to arrive at the

actual current ratings of these conductors under actual operating conditions.

5 Ratings may be improved approximately by 20% if the busbars are painted black with a non-metallic matt finish paint. This is because

the heat dissipation through a surface depends upon its temperature, type of surface and colour. A rough surface dissipates heat more

readily than a smooth surface and a black body more quickly than a normal surface. See also Section 3 1.4.4 and Table 3 1.1.

6 Other gradea as in BS 1474 and BS 2898, for electrical purposes, and as produced by the leading manufacturers, are provided in Table

30.6.

7 To obtain the current rating for any other grade of busbar, multiply the above figures by the appropriate factor defined in Table 30.6.

Table 30.5 Current ratings for rectangular aluminium sections, Grade EIE-M (1350)

Conductor Cro.wsectconu1 I bur 2 barr 3 bars 4 bar7 5 bars 6 bars

ri;e urea ~ ~~~ ~~~~

(mm (rnm?) Approximate ratrngs (A)

25 x 12 30 1 I8 210 285 360 425 480

16 40 151 275 395 490 580 655

20 50 183 320 450 575 675 770

2.5 62 5 223 390 540 685 800 910

30 75 263 480 660 840 990 1 I15

40 100 342 610 860 I080 I260 1425

4x 12 48 156 290 420 536 620 700

16 64 198 340 470 600 710 815

20 80 238 410 570 720 8.50 955

25 100 290 530 755 950 1110 1250

30 120 339 600 845 1060 I245 1400

40 I60 434 750 10.50 1320 1550 1750

50 200 512 905 1260 1575 1825 2035

6x 12 72 200 350 480 610 720 825

16 96 252 450 640 805 960 1075