Page 250 - Industrial Process Plant Construction Estimating and Man Hour Analysis

P. 250

228 Industrial Process Plant Construction Estimating and Man-Hour Analysis

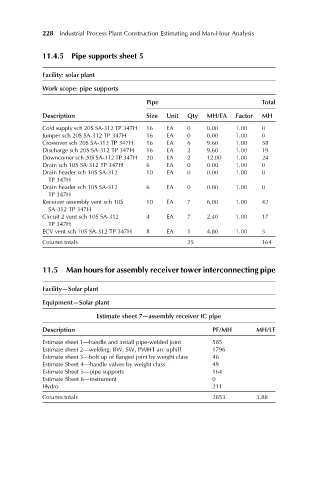

11.4.5 Pipe supports sheet 5

Facility: solar plant

Work scope: pipe supports

Pipe Total

Description Size Unit Qty MH/EA Factor MH

Cold supply sch 20S SA-312 TP 347H 16 EA 0 0.00 1.00 0

Jumper sch 20S SA-312 TP 347H 16 EA 0 0.00 1.00 0

Crossover sch 20S SA-312 TP 347H 16 EA 6 9.60 1.00 58

Discharge sch 20S SA-312 TP 347H 16 EA 2 9.60 1.00 19

Downcomer sch 20S SA-312 TP 347H 20 EA 2 12.00 1.00 24

Drain sch 10S SA-312 TP 347H 6 EA 0 0.00 1.00 0

Drain header sch 10S SA-312 10 EA 0 0.00 1.00 0

TP 347H

Drain header sch 10S SA-312 6 EA 0 0.00 1.00 0

TP 347H

Receiver assembly vent sch 10S 10 EA 7 6.00 1.00 42

SA-312 TP 347H

Circuit 2 vent sch 10S SA-312 4 EA 7 2.40 1.00 17

TP 347H

ECV vent sch 10S SA-312 TP 347H 8 EA 1 4.80 1.00 5

Column totals 25 164

11.5 Man hours for assembly receiver tower interconnecting pipe

Facility—Solar plant

Equipment—Solar plant

Estimate sheet 7—assembly receiver IC pipe

Description PF/MH MH/LF

Estimate sheet 1—handle and install pipe-welded joint 585

Estimate sheet 2—welding: BW, SW, PWHT arc uphill 1796

Estimate sheet 3—bolt up of flanged joint by weight class 46

Estimate Sheet 4—handle valves by weight class 49

Estimate Sheet 5—pipe supports 164

Estimate Sheet 6—instrument 0

Hydro 211

Column totals 2853 3.88