Page 80 - Industrial Process Plant Construction Estimating and Man Hour Analysis

P. 80

Process piping Chapter 2 51

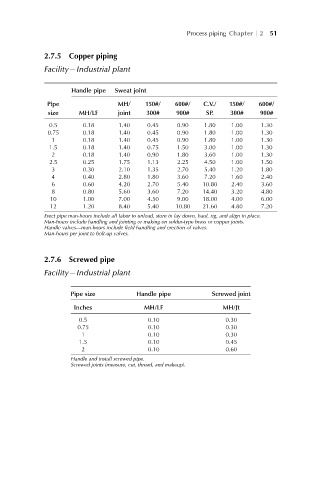

2.7.5 Copper piping

Facility—Industrial plant

Handle pipe Sweat joint

Pipe MH/ 150#/ 600#/ C.V./ 150#/ 600#/

size MH/LF joint 300# 900# SP. 300# 900#

0.5 0.18 1.40 0.45 0.90 1.80 1.00 1.30

0.75 0.18 1.40 0.45 0.90 1.80 1.00 1.30

1 0.18 1.40 0.45 0.90 1.80 1.00 1.30

1.5 0.18 1.40 0.75 1.50 3.00 1.00 1.30

2 0.18 1.40 0.90 1.80 3.60 1.00 1.30

2.5 0.25 1.75 1.13 2.25 4.50 1.00 1.50

3 0.30 2.10 1.35 2.70 5.40 1.20 1.80

4 0.40 2.80 1.80 3.60 7.20 1.60 2.40

6 0.60 4.20 2.70 5.40 10.80 2.40 3.60

8 0.80 5.60 3.60 7.20 14.40 3.20 4.80

10 1.00 7.00 4.50 9.00 18.00 4.00 6.00

12 1.20 8.40 5.40 10.80 21.60 4.80 7.20

Erect pipe man-hours include all labor to unload, store in lay down, haul, rig, and align in place.

Man-hours include handling and jointing or making on solder-type brass or copper joints.

Handle valves—man-hours include field handling and erection of valves.

Man-hours per joint to bolt-up valves.

2.7.6 Screwed pipe

Facility—Industrial plant

Pipe size Handle pipe Screwed joint

Inches MH/LF MH/Jt

0.5 0.10 0.30

0.75 0.10 0.30

1 0.10 0.30

1.5 0.10 0.45

2 0.10 0.60

Handle and install screwed pipe.

Screwed joints (measure, cut, thread, and makeup).