Page 512 - Industrial Wastewater Treatment, Recycling and Reuse

P. 512

482 Industrial Wastewater Treatment, Recycling, and Reuse

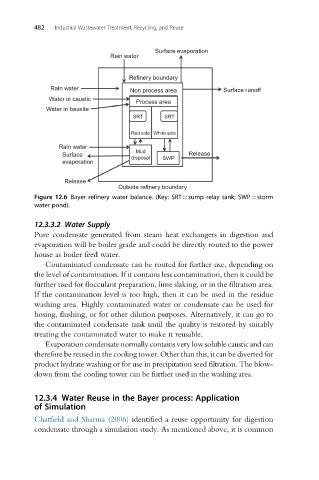

Surface evaporation

Rain water

Refinery boundary

Rain water Non process area Surface runoff

Water in caustic

Process area

Water in bauxite

SRT SRT

Red side White side

Rain water

Mud

Surface Release

disposal SWP

evaporation

Release

Outside refinery boundary

Figure 12.6 Bayer refinery water balance. (Key: SRT¼sump relay tank; SWP¼storm

water pond).

12.3.3.2 Water Supply

Pure condensate generated from steam heat exchangers in digestion and

evaporation will be boiler grade and could be directly routed to the power

house as boiler feed water.

Contaminated condensate can be routed for further use, depending on

the level of contamination. If it contains less contamination, then it could be

further used for flocculant preparation, lime slaking, or in the filtration area.

If the contamination level is too high, then it can be used in the residue

washing area. Highly contaminated water or condensate can be used for

hosing, flushing, or for other dilution purposes. Alternatively, it can go to

the contaminated condensate tank until the quality is restored by suitably

treating the contaminated water to make it reusable.

Evaporation condensate normally containsverylowsoluble caustic and can

therefore be reused in the cooling tower. Other than this, it can be diverted for

product hydrate washing or for use in precipitation seed filtration. The blow-

down from the cooling tower can be further used in the washing area.

12.3.4 Water Reuse in the Bayer process: Application

of Simulation

Chatfield and Sharma (2006) identified a reuse opportunity for digestion

condensate through a simulation study. As mentioned above, it is common