Page 513 - Industrial Wastewater Treatment, Recycling and Reuse

P. 513

Simulation, Control, and Optimization of Water Systems in Industrial Plants 483

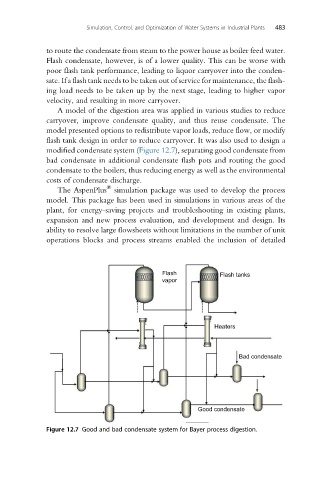

to route the condensate from steam to the power house as boiler feed water.

Flash condensate, however, is of a lower quality. This can be worse with

poor flash tank performance, leading to liquor carryover into the conden-

sate. If a flash tank needs to be taken out of service for maintenance, the flash-

ing load needs to be taken up by the next stage, leading to higher vapor

velocity, and resulting in more carryover.

A model of the digestion area was applied in various studies to reduce

carryover, improve condensate quality, and thus reuse condensate. The

model presented options to redistribute vapor loads, reduce flow, or modify

flash tank design in order to reduce carryover. It was also used to design a

modified condensate system (Figure 12.7), separating good condensate from

bad condensate in additional condensate flash pots and routing the good

condensate to the boilers, thus reducing energy as well as the environmental

costs of condensate discharge.

®

The AspenPlus simulation package was used to develop the process

model. This package has been used in simulations in various areas of the

plant, for energy-saving projects and troubleshooting in existing plants,

expansion and new process evaluation, and development and design. Its

ability to resolve large flowsheets without limitations in the number of unit

operations blocks and process streams enabled the inclusion of detailed

Flash Flash tanks

vapor

Heaters

Bad condensate

Good condensate

Figure 12.7 Good and bad condensate system for Bayer process digestion.