Page 126 - Injection Molding Advanced Troubleshooting Guide

P. 126

13.1 Cavity Pressure Technology 113

Plastic fill rate

Cavity balance

Viscosity shift in material

Gate seal

Pack rate

Pressure drop across the cavity

Cooling rate

Mold or clamp deflection

Valve gate actuation

Process changes

Machine performance

All of the above data is collected on every shot and can be set up with alarm bands

to determine if the part is good or bad while it is still in the mold.

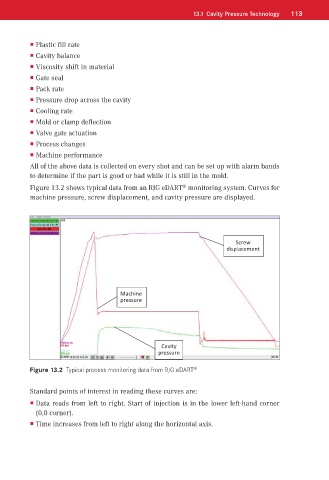

Figure 13.2 shows typical data from an RJG eDART monitoring system. Curves for

®

machine pressure, screw displacement, and cavity pressure are displayed.

Screw

displacement

Machine

pressure

Cavity

pressure

Figure 13.2 Typical process monitoring data from RJG eDART ®

Standard points of interest in reading these curves are:

Data reads from left to right. Start of injection is in the lower left-hand corner

(0,0 corner).

Time increases from left to right along the horizontal axis.