Page 128 - Injection Molding Advanced Troubleshooting Guide

P. 128

13.1 Cavity Pressure Technology 115

Machine

pressure

Screw

displacement

Post gate

cavity

pressure

curves (2)

End of cavity

pressure

curve

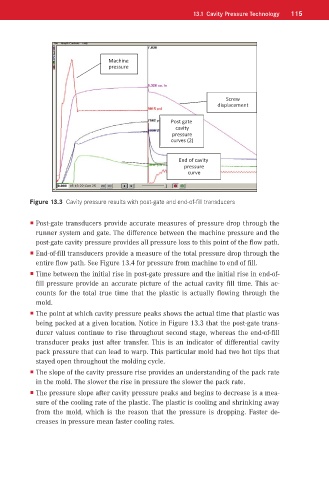

Figure 13.3 Cavity pressure results with post-gate and end-of-fill transducers

Post-gate transducers provide accurate measures of pressure drop through the

runner system and gate. The difference between the machine pressure and the

post-gate cavity pressure provides all pressure loss to this point of the flow path.

End-of-fill transducers provide a measure of the total pressure drop through the

entire flow path. See Figure 13.4 for pressure from machine to end of fill.

Time between the initial rise in post-gate pressure and the initial rise in end-of-

fill pressure provide an accurate picture of the actual cavity fill time. This ac-

counts for the total true time that the plastic is actually flowing through the

mold.

The point at which cavity pressure peaks shows the actual time that plastic was

being packed at a given location. Notice in Figure 13.3 that the post-gate trans-

ducer values continue to rise throughout second stage, whereas the end-of-fill

transducer peaks just after transfer. This is an indicator of differential cavity

pack pressure that can lead to warp. This particular mold had two hot tips that

stayed open throughout the molding cycle.

The slope of the cavity pressure rise provides an understanding of the pack rate

in the mold. The slower the rise in pressure the slower the pack rate.

The pressure slope after cavity pressure peaks and begins to decrease is a mea-

sure of the cooling rate of the plastic. The plastic is cooling and shrinking away

from the mold, which is the reason that the pressure is dropping. Faster de-

creases in pressure mean faster cooling rates.