Page 132 - Injection Molding Advanced Troubleshooting Guide

P. 132

13.2 Cavity Thermocouples 119

The data obtained from cavity thermocouples are not as detailed as is the case with

cavity pressure; however, thermocouples will provide the following:

Actual mold steel temperature

Actual fill time to the thermocouple location

Change to melt temperature or cooling rate

An advantage of cavity thermocouples is that they are extremely fast-acting, which

makes them very useful for setting up valve gate actuation. By using cavity ther-

mocouples positioned throughout the mold, sequential valve gate actuation can be

very accurate, and the gate does not actuate until the plastic has reached a specific

point in the cavity. The equipment can be set up to delay firing based on time after

a temperature rise at a given thermocouple. This is a very repeatable way of setting

up sequential valve gate actuation.

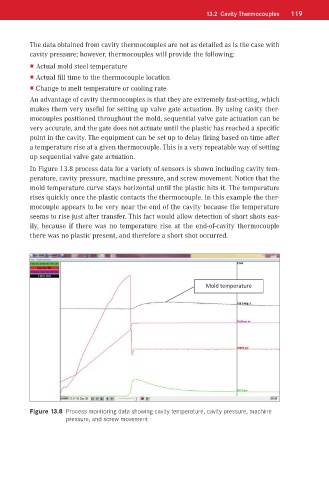

In Figure 13.8 process data for a variety of sensors is shown including cavity tem-

perature, cavity pressure, machine pressure, and screw movement. Notice that the

mold temperature curve stays horizontal until the plastic hits it. The temperature

rises quickly once the plastic contacts the thermocouple. In this example the ther-

mocouple appears to be very near the end of the cavity because the temperature

seems to rise just after transfer. This fact would allow detection of short shots eas-

ily, because if there was no temperature rise at the end-of-cavity thermocouple

there was no plastic present, and therefore a short shot occurred.

Mold temperature

Figure 13.8 Process monitoring data showing cavity temperature, cavity pressure, machine

pressure, and screw movement