Page 134 - Injection Molding Advanced Troubleshooting Guide

P. 134

13.3 Process Documentation 121

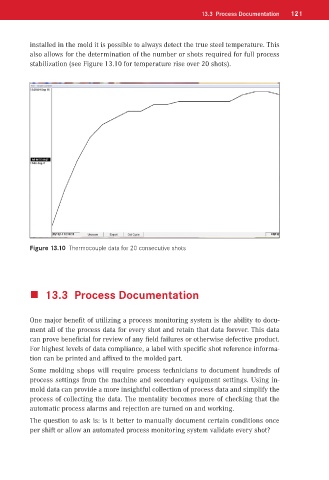

installed in the mold it is possible to always detect the true steel temperature. This

also allows for the determination of the number or shots required for full process

stabilization (see Figure 13.10 for temperature rise over 20 shots).

Figure 13.10 Thermocouple data for 20 consecutive shots

13.3 Process Documentation

One major benefit of utilizing a process monitoring system is the ability to docu-

ment all of the process data for every shot and retain that data forever. This data

can prove beneficial for review of any field failures or otherwise defective product.

For highest levels of data compliance, a label with specific shot reference informa-

tion can be printed and affixed to the molded part.

Some molding shops will require process technicians to document hundreds of

process settings from the machine and secondary equipment settings. Using in-

mold data can provide a more insightful collection of process data and simplify the

process of collecting the data. The mentality becomes more of checking that the

automatic process alarms and rejection are turned on and working.

The question to ask is: is it better to manually document certain conditions once

per shift or allow an automated process monitoring system validate every shot?