Page 161 - Injection Molding Advanced Troubleshooting Guide

P. 161

16.3 Blush Troubleshooting 149

16.3.3.2 Machine: Machine Performance

To avoid blush it is always important to ensure that the machine is achieving the

required set points for all parameters.

For details see Chapter 8 on machine performance.

16.3.4 Blush Troubleshooting Material Issues

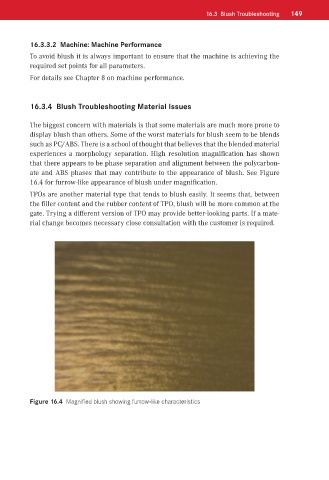

The biggest concern with materials is that some materials are much more prone to

display blush than others. Some of the worst materials for blush seem to be blends

such as PC/ABS. There is a school of thought that believes that the blended material

experiences a morphology separation. High resolution magnification has shown

that there appears to be phase separation and alignment between the polycarbon-

ate and ABS phases that may contribute to the appearance of blush. See Figure

16.4 for furrow-like appearance of blush under magnification.

TPOs are another material type that tends to blush easily. It seems that, between

the filler content and the rubber content of TPO, blush will be more common at the

gate. Trying a different version of TPO may provide better-looking parts. If a mate-

rial change becomes necessary close consultation with the customer is required.

Figure 16.4 Magnified blush showing furrow-like characteristics