Page 163 - Injection Molding Advanced Troubleshooting Guide

P. 163

152 17 Brown Streaks

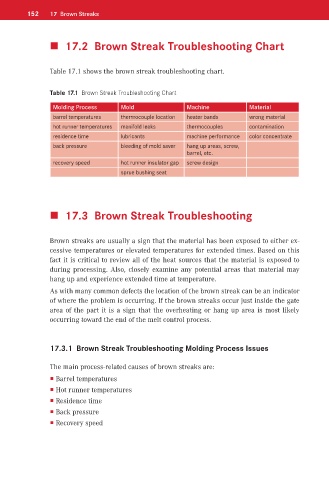

17.2 Brown Streak Troubleshooting Chart

Table 17.1 shows the brown streak troubleshooting chart.

Table 17.1 Brown Streak Troubleshooting Chart

Molding Process Mold Machine Material

barrel temperatures thermocouple location heater bands wrong material

hot runner temperatures manifold leaks thermocouples contamination

residence time lubricants machine performance color concentrate

back pressure bleeding of mold saver hang up areas, screw,

barrel, etc.

recovery speed hot runner insulator gap screw design

sprue bushing seat

17.3 Brown Streak Troubleshooting

Brown streaks are usually a sign that the material has been exposed to either ex-

cessive temperatures or elevated temperatures for extended times. Based on this

fact it is critical to review all of the heat sources that the material is exposed to

during processing. Also, closely examine any potential areas that material may

hang up and experience extended time at temperature.

As with many common defects the location of the brown streak can be an indicator

of where the problem is occurring. If the brown streaks occur just inside the gate

area of the part it is a sign that the overheating or hang up area is most likely

occurring toward the end of the melt control process.

17.3.1 Brown Streak Troubleshooting Molding Process Issues

The main process-related causes of brown streaks are:

Barrel temperatures

Hot runner temperatures

Residence time

Back pressure

Recovery speed