Page 165 - Injection Molding Advanced Troubleshooting Guide

P. 165

154 17 Brown Streaks

Examination of the hot runner controller during this time period showed that

none of the control zones were registering anything out of the ordinary. To

determine if the hot runner controller was the problem it was switched with

another controller. When running with the new controller there were no

scrap issues and no variation in temperature on the monitoring thermo-

couples was observed. To verify that the controller was the issue the original

controller was again used to run the mold, which in turn resulted in high

scrap and excess temperature deviation on the monitoring thermocouples.

Hot runner cables are another area that can create problems. Something as simple

as having a wrongly wired cable can lead to problems. The cable must be wired

such that each zone is correctly attached to the pin at each end of the cable; in

other words pin 1 on plug 1 must be wired to pin 1 on plug 2. Cables can be

swapped out to verify that they are not the root cause, and if the cables are swapped

and the problem is resolved the original cable should be checked for continuity

from one plug to the other.

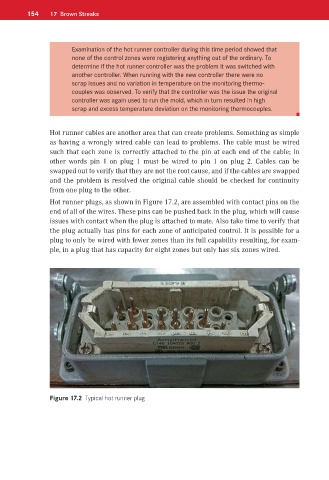

Hot runner plugs, as shown in Figure 17.2, are assembled with contact pins on the

end of all of the wires. These pins can be pushed back in the plug, which will cause

issues with contact when the plug is attached to mate. Also take time to verify that

the plug actually has pins for each zone of anticipated control. It is possible for a

plug to only be wired with fewer zones than its full capability resulting, for exam-

ple, in a plug that has capacity for eight zones but only has six zones wired.

Figure 17.2 Typical hot runner plug