Page 169 - Injection Molding Advanced Troubleshooting Guide

P. 169

158 17 Brown Streaks

17.3.2.4 Mold: Hot Runner Insulator Gap

Many hot runner tips have an insulator gap that helps to isolate the hot runner

heat from the cavity. If these gaps are not sealed (most hot runner manufacturers

supply seals to fill these gaps) material will become trapped and can potentially

degrade leading to brown streaks. These gaps can also create major issues when

conducting color changes.

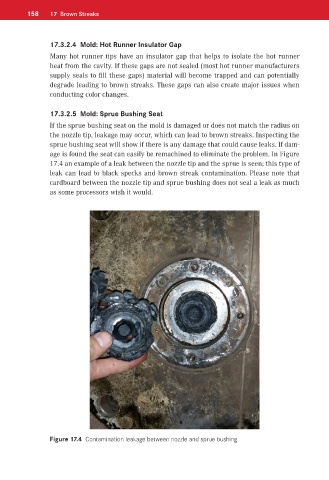

17.3.2.5 Mold: Sprue Bushing Seat

If the sprue bushing seat on the mold is damaged or does not match the radius on

the nozzle tip, leakage may occur, which can lead to brown streaks. Inspecting the

sprue bushing seat will show if there is any damage that could cause leaks. If dam-

age is found the seat can easily be remachined to eliminate the problem. In Figure

17.4 an example of a leak between the nozzle tip and the sprue is seen; this type of

leak can lead to black specks and brown streak contamination. Please note that

cardboard between the nozzle tip and sprue bushing does not seal a leak as much

as some processors wish it would.

Figure 17.4 Contamination leakage between nozzle and sprue bushing