Page 173 - Injection Molding Advanced Troubleshooting Guide

P. 173

162 17 Brown Streaks

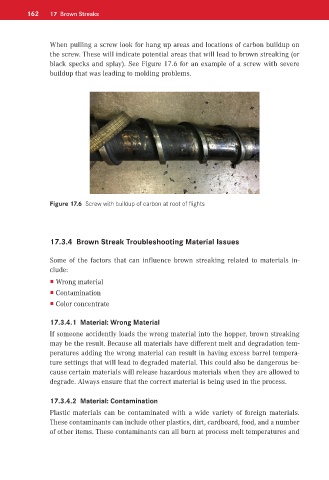

When pulling a screw look for hang up areas and locations of carbon buildup on

the screw. These will indicate potential areas that will lead to brown streaking (or

black specks and splay). See Figure 17.6 for an example of a screw with severe

buildup that was leading to molding problems.

Figure 17.6 Screw with buildup of carbon at root of flights

17.3.4 Brown Streak Troubleshooting Material Issues

Some of the factors that can influence brown streaking related to materials in-

clude:

Wrong material

Contamination

Color concentrate

17.3.4.1 Material: Wrong Material

If someone accidently loads the wrong material into the hopper, brown streaking

may be the result. Because all materials have different melt and degradation tem-

peratures adding the wrong material can result in having excess barrel tempera-

ture settings that will lead to degraded material. This could also be dangerous be-

cause certain materials will release hazardous materials when they are allowed to

degrade. Always ensure that the correct material is being used in the process.

17.3.4.2 Material: Contamination

Plastic materials can be contaminated with a wide variety of foreign materials.

These contaminants can include other plastics, dirt, cardboard, food, and a number

of other items. These contaminants can all burn at process melt temperatures and