Page 380 - Injection Molding Advanced Troubleshooting Guide

P. 380

378 40 Short Shot

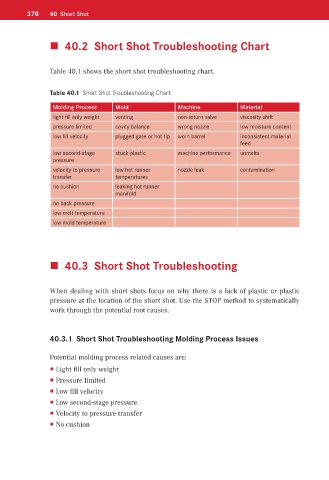

40.2 Short Shot Troubleshooting Chart

Table 40.1 shows the short shot troubleshooting chart.

Table 40.1 Short Shot Troubleshooting Chart

Molding Process Mold Machine Material

light fill only weight venting non-return valve viscosity shift

pressure limited cavity balance wrong nozzle low moisture content

low fill velocity plugged gate or hot tip worn barrel inconsistent material

feed

low second-stage stuck plastic machine performance unmelts

pressure

velocity to pressure low hot runner nozzle leak contamination

transfer temperatures

no cushion leaking hot runner

manifold

no back pressure

low melt temperature

low mold temperature

40.3 Short Shot Troubleshooting

When dealing with short shots focus on why there is a lack of plastic or plastic

pressure at the location of the short shot. Use the STOP method to systematically

work through the potential root causes.

40.3.1 Short Shot Troubleshooting Molding Process Issues

Potential molding process related causes are:

Light fill only weight

Pressure limited

Low fill velocity

Low second-stage pressure

Velocity to pressure transfer

No cushion