Page 383 - Injection Molding Advanced Troubleshooting Guide

P. 383

40.3 Short Shot Troubleshooting 381

40.3.1.3 Molding Process: Low Fill Velocity

If first-stage injection velocity is set too slow the mold will not fill completely. In

most processes filling the mold fast is desirable because fast fill velocities help

maintain a more consistent viscosity and limit the amount of pressure drop while

filling the mold.

Verify that the machine is achieving the required fill time. If fill time is too long the

actual first-stage velocity is likely too slow. If the fill time is not being achieved

raise the velocity setting to achieve the documented fill time. Fill time and fill only

weight are the normally used measures of actual volumetric flow rate. The fill ve-

locity set point on the machine controller may not mean anything; for example,

some machines use percent as the set point for velocity. Always rely on fill only

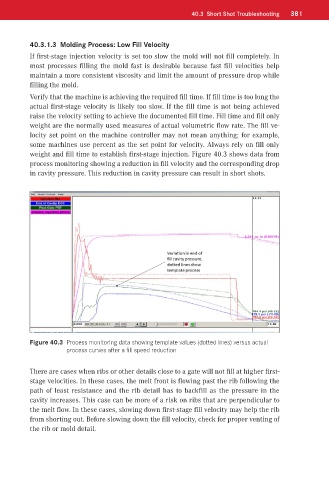

weight and fill time to establish first-stage injection. Figure 40.3 shows data from

process monitoring showing a reduction in fill velocity and the corresponding drop

in cavity pressure. This reduction in cavity pressure can result in short shots.

Figure 40.3 Process monitoring data showing template values (dotted lines) versus actual

process curves after a fill speed reduction

There are cases when ribs or other details close to a gate will not fill at higher first-

stage velocities. In these cases, the melt front is flowing past the rib following the

path of least resistance and the rib detail has to backfill as the pressure in the

cavity increases. This case can be more of a risk on ribs that are perpendicular to

the melt flow. In these cases, slowing down first-stage fill velocity may help the rib

from shorting out. Before slowing down the fill velocity, check for proper venting of

the rib or mold detail.