Page 71 - Injection Molding Advanced Troubleshooting Guide

P. 71

7.1 Venting Basics 55

interior of a framed part the relief cannot be directed to the exterior of the mold

base, and in this case the relief should be directed to a vent hole that allows the gas

to exit through the back of the core retainer plate. Always add a pin to each vent

hole to ensure that the hole does not flash over.

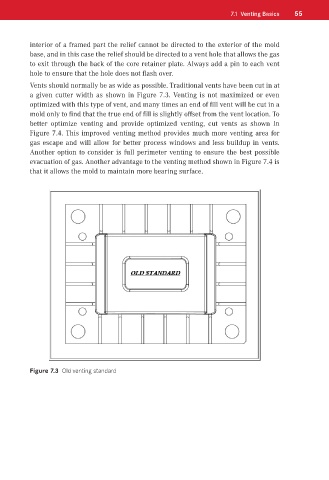

Vents should normally be as wide as possible. Traditional vents have been cut in at

a given cutter width as shown in Figure 7.3. Venting is not maximized or even

optimized with this type of vent, and many times an end of fill vent will be cut in a

mold only to find that the true end of fill is slightly offset from the vent location. To

better optimize venting and provide optimized venting, cut vents as shown in

Figure 7.4. This improved venting method provides much more venting area for

gas escape and will allow for better process windows and less buildup in vents.

Another option to consider is full perimeter venting to ensure the best possible

evacuation of gas. Another advantage to the venting method shown in Figure 7.4 is

that it allows the mold to maintain more bearing surface.

Figure 7.3 Old venting standard