Page 75 - Injection Molding Advanced Troubleshooting Guide

P. 75

7.2 Alternate Venting 59

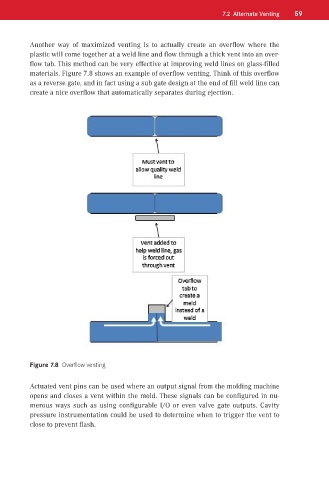

Another way of maximized venting is to actually create an overflow where the

plastic will come together at a weld line and flow through a thick vent into an over-

flow tab. This method can be very effective at improving weld lines on glass-filled

materials. Figure 7.8 shows an example of overflow venting. Think of this overflow

as a reverse gate, and in fact using a sub gate design at the end of fill weld line can

create a nice overflow that automatically separates during ejection.

Figure 7.8 Overflow venting

Actuated vent pins can be used where an output signal from the molding machine

opens and closes a vent within the mold. These signals can be configured in nu-

merous ways such as using configurable I/O or even valve gate outputs. Cavity

pressure instrumentation could be used to determine when to trigger the vent to

close to prevent flash.