Page 80 - Injection Molding Advanced Troubleshooting Guide

P. 80

64 8 Machine Performance

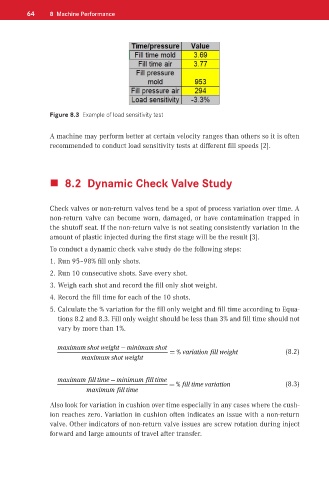

Figure 8.3 Example of load sensitivity test

A machine may perform better at certain velocity ranges than others so it is often

recommended to conduct load sensitivity tests at different fill speeds [2].

8.2 Dynamic Check Valve Study

Check valves or non-return valves tend be a spot of process variation over time. A

non-return valve can become worn, damaged, or have contamination trapped in

the shutoff seat. If the non-return valve is not seating consistently variation in the

amount of plastic injected during the first stage will be the result [3].

To conduct a dynamic check valve study do the following steps:

1. Run 95–98% fill only shots.

2. Run 10 consecutive shots. Save every shot.

3. Weigh each shot and record the fill only shot weight.

4. Record the fill time for each of the 10 shots.

5. Calculate the % variation for the fill only weight and fill time according to Equa-

tions 8.2 and 8.3. Fill only weight should be less than 3% and fill time should not

vary by more than 1%.

maximum shot weight − minimum shot = % variaation fill weight (8.2)

maximum shot weight

maximum fill time− minimum fill time = % filll time variation (8.3)

maximum fill time

Also look for variation in cushion over time especially in any cases where the cush-

ion reaches zero. Variation in cushion often indicates an issue with a non-return

valve. Other indicators of non-return valve issues are screw rotation during inject

forward and large amounts of travel after transfer.