Page 72 - Injection Molding Advanced Troubleshooting Guide

P. 72

56 7 Venting

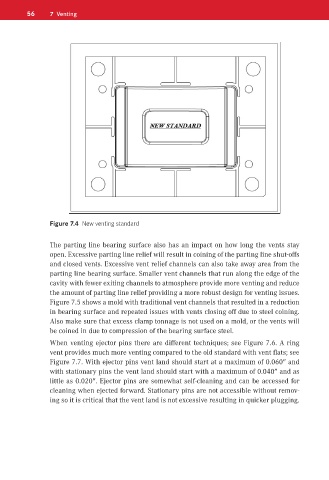

Figure 7.4 New venting standard

The parting line bearing surface also has an impact on how long the vents stay

open. Excessive parting line relief will result in coining of the parting line shut-offs

and closed vents. Excessive vent relief channels can also take away area from the

parting line bearing surface. Smaller vent channels that run along the edge of the

cavity with fewer exiting channels to atmosphere provide more venting and reduce

the amount of parting line relief providing a more robust design for venting issues.

Figure 7.5 shows a mold with traditional vent channels that resulted in a reduction

in bearing surface and repeated issues with vents closing off due to steel coining.

Also make sure that excess clamp tonnage is not used on a mold, or the vents will

be coined in due to compression of the bearing surface steel.

When venting ejector pins there are different techniques; see Figure 7.6. A ring

vent provides much more venting compared to the old standard with vent flats; see

Figure 7.7. With ejector pins vent land should start at a maximum of 0.060″ and

with stationary pins the vent land should start with a maximum of 0.040″ and as

little as 0.020″. Ejector pins are somewhat self-cleaning and can be accessed for

cleaning when ejected forward. Stationary pins are not accessible without remov-

ing so it is critical that the vent land is not excessive resulting in quicker plugging.