Page 265 - Instrumentation Reference Book 3E

P. 265

Measurement techniques: direct effects 249

L 1

Figure 14.7 Formsfor bulbsfor mercury-in-steel

thermometers.

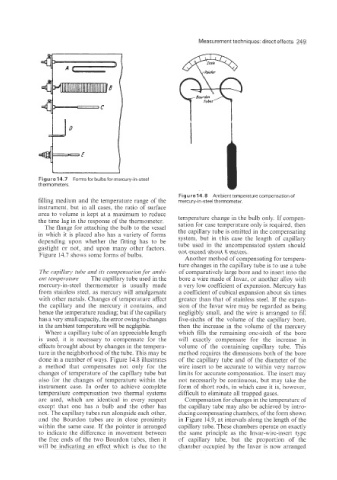

Figure 14.8 Ambient temperaturecompensation of

filling medium and the temperature range of the mercury-in-steel thermometer.

instrument. but in all cases, the ratio of surface

area to volume is kept at a maximum to reduce

the time lag in the response of the thermometer. temperature change in the bulb only. If compen-

The flange for attaching the bulb to the vessel sation for case temperature only is required, then

in which it is placed also has a variety of forms the capillary tube is omitted in the compensating

depending upon whether the fitting has to be system, but in this case the length of capillary

gastight or not, and upon many other factors. tube used in the uncompensated system should

Figure 14.7 shows some forms of bulbs. not exceed about 8 meters.

Another method of compensating for tempera-

ture changes in the capillary tube is to use a tube

The capillary tube and its coinpensation for ambi- of comparatively large bore and to insert into the

ent temperature The capillary tube used in the bore a wire made of Invar, or another alloy with

mercury-in-steel thermometer is usually made a very low coefficient of expansion. Mercury has

from stainless steel, as mercury will amalgamate a coefficient of cubical expansion about six times

with other metals. Changes of temperature affect greater than that of stainless steel. If the expan-

the capillary and the mercury it contains, and sion of the Invar wire may be regarded as being

hence the kemperature reading; but if the capillary negligibly small, and the wire is arranged to fill

has a very small capacity, the error owing to changes five-sixths of the volume of the capillary bore,

in the ambient temperature will be negligible. then the increase in the volume of the mercury

Where a capillary tube of an appreciable length which fills the remaining one-sixth of the bore

is used, it is necessary to compensate for the will exactly compensate for the increase in

effects brought about by changes in the tempera- volume of the containing capillary tube. This

ture in the neighborhood of the tube. This may be method requires the dimensions both of the bore

done in a number of ways. Figure 14.8 illustrates of the capillary tube and of the diameter of the

a method that Compensates not only for the wire insert to be accurate io within very narrow

changes of temperature of the capillary tube but limits for accurate compensation. The insert may

also for the changes of temperature within the not necessarily be continuous, but may take the

instrument case. In order to achieve complete form of short rods, in which case it is, however,

temperature compensation two thermal systems difficult to eliminate all trapped gases.

are used, which are identical in every respect Compensation for changes in the temperature of

except that one has a bulb and the other has the capillary tube may also be achieved by intro-

not. The capillary tubes run alongside each other, ducing compensating chambers, of the form shown

and the Bourdon tubes are in close proximity in Figure 14.9, at intervals along the length of the

within the same case. If the pointer is arranged capillary tube. These chambers operate on exactly

to indicate the difference in movement between the same principle as the Invar-wire-insert type

the free ends of the two Bourdon tubes, then it of capillary tube, but the proportion of the

will be indicating an effect which is due to the chamber occupied by the Invar is now arranged