Page 271 - Instrumentation Reference Book 3E

P. 271

Measurement techniques: direct effects 255

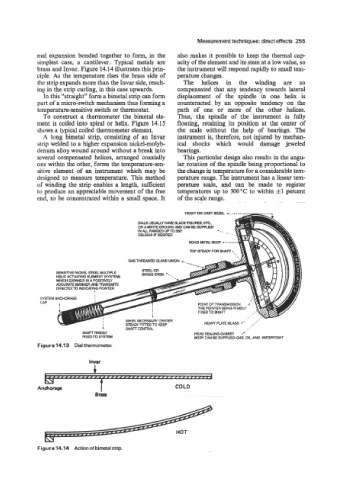

mal expansion bonded together to form, in the also makes it possible to keep the thermal cap-

simplest case, a cantilever. Typical metals are acity of the element and its stem at a low value, so

brass and Invar. Figure 14.14 illustrates this prin- the instrument will respond rapidly to small tem-

ciple. As The temperature rises the brass side of perature changes.

the strip expands more than the Invar side, result- The helices in the winding are so

ing in the strip curling, in this case upwards. compensated that any tendency towards lateral

In this “straight” form a bimetal strip can form displacement of the spindle in one helix is

part of a micro-switch mechanism thus forming a counteracted by an opposite tendency on the

temperature-sensitive switch or thermostat. path of one or more of the other helices.

To construct a thermometer the bimetal ele- Thus, the spindle of the instrument is fully

ment is coiled into spiral or helix. Figure 14.15 floating, retaining its position at the center of

shows a typical coiled thermometer element. the scale without the help of bearings. The

A long bimetal strip, consisting of an Invar instrument is, therefore, not injured by mechan-

strip welded to a higher expansion nickel-molyb- ical shocks which would damage jeweled

denum alloy wound around without a break into bearings.

several compensated helices, arranged coaxially This particular design also results in the angu-

one within the other, forms the temperature-sen- lar rotation of the spindle being proportional to

sitive element of an instrument which may be the change in temperature for a considerable tem-

designed to measure temperature. This method perature range. The instrument has a linear tem-

of winding the strip enables a length, sufficient perature scale, and can be made to register

to produce an appreciable movement of the free temperatures up to 300°C to within fl percent

end, to be concentrated within a small space. It of the scale range.

HEAWDIECASTBEZEL -..-

DIALS USUALLY HAVE BLACK FIGURES, EX..

ON A WHITE GROUND AND CAN BE SUPPLIED

IN ALL RANGES UPTO 560’

CELSIUS IF DESIRED

STEEL OR

SENSITIVE NICKEL STEEL MULTIPLE

DIRECTLY TO INDICATIFJG P

SYSTEM

CAP POINTOFTRANSMISSION ;

THE POINTER BEING RIGIDLY

FIXED TO SHAFT

WHEN NECESSARY CENTER

, STEADY FITTED TO KEEP HEAWPLATEGLASS ’ ,:

SHAFT CENTRAL

SHAFT RIGIDLY HEAD SEALING GASKET -‘.

FIXEDTO SYSTEM BOW CAN BE SUPPLIEPGAS, OIL, AND WATERTIGHT

Figure 14.13 Dial thermometer.

lnvar

Figure 14.14 Action of bimetal strip.