Page 84 - Instrumentation Reference Book 3E

P. 84

Automatic gauging systems 69

representing one or many length dimensions.

In simple applications the operator places the

component in a preset, multiprobe system. In

a totally automated plant use is often made of

pick-and-place robots to load the inspection

machines.

Automatic inspection systems began their

development in the 1950s when they were

required to complement the then emerging

numerically controlled metal-working machine

tools. They made use of similar measuring sen-

sors as did the tools but differed from the metal

working machine in several ways.

Where inspection machines are hand-operated

the operator can work best when the system effect-

ively presents no significant inertial forces to the

input probe as it is moved. This can be achieved

by a design that minimizes the moving masses or

by the use of closed-loop sensor control that

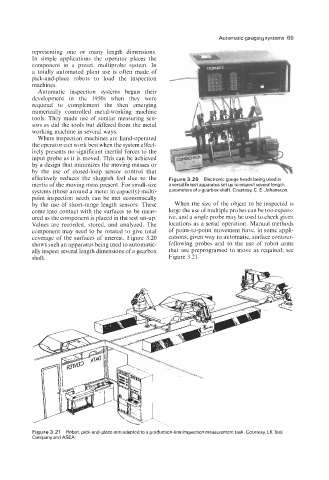

effectively reduces the sluggish feel due to the Figure 3.20 Electronic gauge heads being used in

inertia of the moving mass present. For small-size a versatile test apparatus set up to inspect several length

systems (those around a meter in capacity) multi- parameters of a gearbox shaft. Courtesy, C. E. Johansson.

point inspection needs can be met economically

by the use of short-range length sensors. These When the size of the object to be inspected is

come into contact with the surfaces to be meas- large the use of multiple probes can be too expens-

ured as the component is placed in the test set-up. ive, and a single probe may be used to check given

Values are recorded, stored, and analyzed. The locations as a serial operation. Manual methods

component may need to be rotated to give total of point-to-point movement have, in some appli-

coverage of the surfaces of interest. Figure 3.20 cations, given way to automatic, surface contour-

shows such an apparatus being used to automatic- following probes and to the use of robot arms

ally inspect several length dimensions of a gearbox that are preprogramed to move as required; see

shaft. Figure 3.21.

Figure 3.21 Robot, pick-and-place arm adapted to a production-line inspection measurement task. Courtesy, LK Tool

Company and ASEA.