Page 53 - Materials Chemistry, Second Edition

P. 53

L1644_C01.fm Page 29 Monday, October 20, 2003 11:46 AM

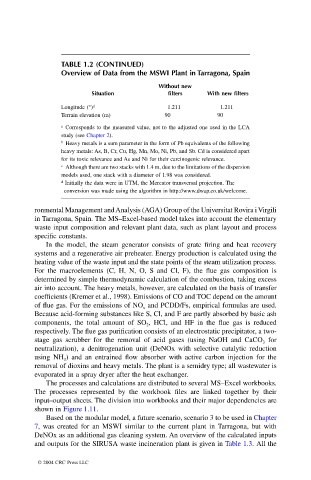

TABLE 1.2 (CONTINUED)

Overview of Data from the MSWI Plant in Tarragona, Spain

Without new

Situation filters With new filters

Longitude (∞) d 1.211 1.211

Terrain elevation (m) 90 90

a Corresponds to the measured value, not to the adjusted one used in the LCA

study (see Chapter 2).

b Heavy metals is a sum parameter in the form of Pb equivalents of the following

heavy metals: As, B, Cr, Cu, Hg, Mn, Mo, Ni, Pb, and Sb. Cd is considered apart

for its toxic relevance and As and Ni for their carcinogenic relevance.

c Although there are two stacks with 1.4 m, due to the limitations of the dispersion

models used, one stack with a diameter of 1.98 was considered.

d Initially the data were in UTM, the Mercator transversal projection. The

conversion was made using the algorithm in http://www.dwap.co.uk/welcome.

;

ronmental Management and Analysis (AGA) Group of the Universitat Rovira i Virgili

in Tarragona, Spain. The MS–Excel-based model takes into account the elementary

waste input composition and relevant plant data, such as plant layout and process

specific constants.

In the model, the steam generator consists of grate firing and heat recovery

systems and a regenerative air preheater. Energy production is calculated using the

heating value of the waste input and the state points of the steam utilization process.

For the macroelements (C, H, N, O, S and Cl, F), the flue gas composition is

determined by simple thermodynamic calculation of the combustion, taking excess

air into account. The heavy metals, however, are calculated on the basis of transfer

coefficients (Kremer et al., 1998). Emissions of CO and TOC depend on the amount

of flue gas. For the emissions of NO and PCDD/Fs, empirical formulas are used.

x

Because acid-forming substances like S, Cl, and F are partly absorbed by basic ash

components, the total amount of SO , HCl, and HF in the flue gas is reduced

2

respectively. The flue gas purification consists of an electrostatic precipitator, a two-

stage gas scrubber for the removal of acid gases (using NaOH and CaCO for

3

neutralization), a denitrogenation unit (DeNOx with selective catalytic reduction

using NH ) and an entrained flow absorber with active carbon injection for the

3

removal of dioxins and heavy metals. The plant is a semidry type; all wastewater is

evaporated in a spray dryer after the heat exchanger.

The processes and calculations are distributed to several MS–Excel workbooks.

The processes represented by the workbook files are linked together by their

input–output sheets. The division into workbooks and their major dependencies are

shown in Figure 1.11.

Based on the modular model, a future scenario, scenario 3 to be used in Chapter

7, was created for an MSWI similar to the current plant in Tarragona, but with

DeNOx as an additional gas cleaning system. An overview of the calculated inputs

and outputs for the SIRUSA waste incineration plant is given in Table 1.3. All the

© 2004 CRC Press LLC