Page 208 - Intelligent Digital Oil And Gas Fields

P. 208

162 +Gains A B Manual System. Offline process. High level of

Intelligent Digital Oil and Gas Fields

Production performance with and without DOF −Loses Sustained gains C Automated but nonoptimized system. Online

downtime production. Human Intervention. 24

hours delays in response

process. Human intervention for controls.

Automated and optimized system. Online process.

Human intervention for controls

D

Automated and optimized system with smart

control process connected to loT. Online process.

Automated control with human supervision.

Time in months

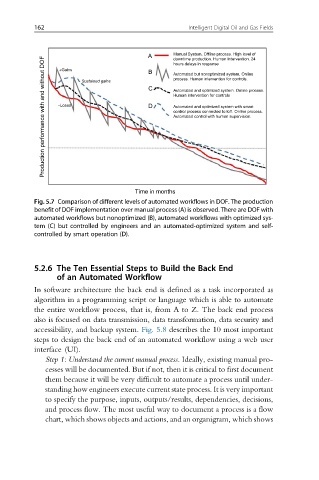

Fig. 5.7 Comparison of different levels of automated workflows in DOF. The production

benefit of DOF implementation over manual process (A) is observed. There are DOF with

automated workflows but nonoptimized (B), automated workflows with optimized sys-

tem (C) but controlled by engineers and an automated-optimized system and self-

controlled by smart operation (D).

5.2.6 The Ten Essential Steps to Build the Back End

of an Automated Workflow

In software architecture the back end is defined as a task incorporated as

algorithm in a programming script or language which is able to automate

the entire workflow process, that is, from A to Z. The back end process

also is focused on data transmission, data transformation, data security and

accessibility, and backup system. Fig. 5.8 describes the 10 most important

steps to design the back end of an automated workflow using a web user

interface (UI).

Step 1: Understand the current manual process. Ideally, existing manual pro-

cesses will be documented. But if not, then it is critical to first document

them because it will be very difficult to automate a process until under-

standing how engineers execute current state process. It is very important

to specify the purpose, inputs, outputs/results, dependencies, decisions,

and process flow. The most useful way to document a process is a flow

chart, which shows objects and actions, and an organigram, which shows