Page 228 - Intro Predictive Maintenance

P. 228

Process Parameters 219

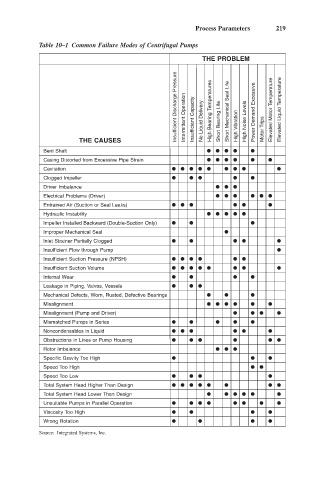

Table 10–1 Common Failure Modes of Centrifugal Pumps

THE PROBLEM

Insufficient Discharge Pressure Intermittent Operation Insufficient Capacity No Liquid Delivery High Bearing Temperatures Short Bearing Life Short Mechanical Seal Life High Noise Levels Power Demand Excessive Elevated Motor Temperature Elevated Liquid Temperature

THE CAUSES High Vibration Motor Trips

Bent Shaft

Casing Distorted from Excessive Pipe Strain

Cavitation

Clogged Impeller

Driver Imbalance

Electrical Problems (Driver)

Entrained Air (Suction or Seal Leaks)

Hydraulic Instability

Impeller Installed Backward (Double-Suction Only)

Improper Mechanical Seal

Inlet Strainer Partially Clogged

Insufficient Flow through Pump

Insufficient Suction Pressure (NPSH)

Insufficient Suction Volume

Internal Wear

Leakage in Piping, Valves, Vessels

Mechanical Defects, Worn, Rusted, Defective Bearings

Misalignment

Misalignment (Pump and Driver)

Mismatched Pumps in Series

Noncondensables in Liquid

Obstructions in Lines or Pump Housing

Rotor Imbalance

Specific Gravity Too High

Speed Too High

Speed Too Low

Total System Head Higher Than Design

Total System Head Lower Than Design

Unsuitable Pumps in Parallel Operation

Viscosity Too High

Wrong Rotation

Source: Integrated Systems, Inc.