Page 233 - Intro Predictive Maintenance

P. 233

224 An Introduction to Predictive Maintenance

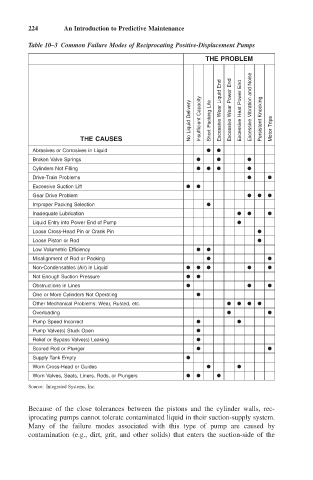

Table 10–3 Common Failure Modes of Reciprocating Positive-Displacement Pumps

THE PROBLEM

No Liquid Delivery Insufficient Capacity Short Packing Life Excessive Wear Liquid End Excessive Wear Power End Excessive Heat Power End Excessive Vibration and Noise Persistent Knocking Motor Trips

THE CAUSES

Abrasives or Corrosives in Liquid

Broken Valve Springs

Cylinders Not Filling

Drive-Train Problems

Excessive Suction Lift

Gear Drive Problem

Improper Packing Selection

Inadequate Lubrication

Liquid Entry into Power End of Pump

Loose Cross-Head Pin or Crank Pin

Loose Piston or Rod

Low Volumetric Efficiency

Misalignment of Rod or Packing

Non-Condensables (Air) in Liquid

Not Enough Suction Pressure

Obstructions in Lines

One or More Cylinders Not Operating

Other Mechanical Problems: Wear, Rusted, etc.

Overloading

Pump Speed Incorrect

Pump Valve(s) Stuck Open

Relief or Bypass Valve(s) Leaking

Scored Rod or Plunger

Supply Tank Empty

Worn Cross-Head or Guides

Worn Valves, Seats, Liners, Rods, or Plungers

Source: Integrated Systems, Inc.

Because of the close tolerances between the pistons and the cylinder walls, rec-

iprocating pumps cannot tolerate contaminated liquid in their suction-supply system.

Many of the failure modes associated with this type of pump are caused by

contamination (e.g., dirt, grit, and other solids) that enters the suction-side of the