Page 235 - Intro Predictive Maintenance

P. 235

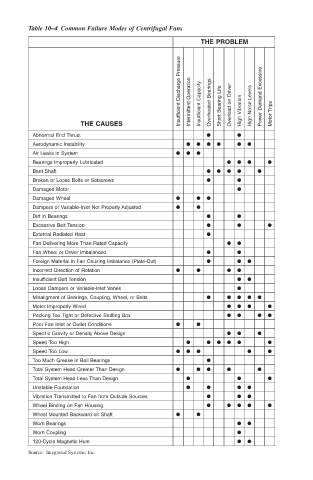

Table 10–4 Common Failure Modes of Centrifugal Fans

THE PROBLEM

Insufficient Discharge Pressure Intermittent Operation Insufficient Capacity Overheated Bearings Short Bearing Life Overload on Driver High Noise Levels Power Demand Excessive

THE CAUSES High Vibration Motor Trips

Abnormal End Thrust

Aerodynamic Instability

Air Leaks in System

Bearings Improperly Lubricated

Bent Shaft

Broken or Loose Bolts or Setscrews

Damaged Motor

Damaged Wheel

Dampers or Variable-Inlet Not Properly Adjusted

Dirt in Bearings

Excessive Belt Tension

External Radiated Heat

Fan Delivering More Than Rated Capacity

Fan Wheel or Driver Imbalanced

Foreign Material in Fan Causing Imbalance (Plate-Out)

Incorrect Direction of Rotation

Insufficient Belt Tension

Loose Dampers or Variable-Inlet Vanes

Misaligment of Bearings, Coupling, Wheel, or Belts

Motor Improperly Wired

Packing Too Tight or Defective Stuffing Box

Poor Fan Inlet or Outlet Conditions

Specific Gravity or Density Above Design

Speed Too High

Speed Too Low

Too Much Grease in Ball Bearings

Total System Head Greater Than Design

Total System Head Less Than Design

Unstable Foundation

Vibration Transmitted to Fan from Outside Sources

Wheel Binding on Fan Housing

Wheel Mounted Backward on Shaft

Worn Bearings

Worn Coupling

120-Cycle Magnetic Hum

Source: Integrated Systems, Inc.