Page 240 - Intro Predictive Maintenance

P. 240

Process Parameters 231

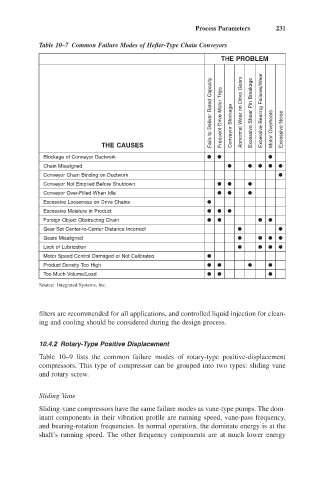

Table 10–7 Common Failure Modes of Hefler-Type Chain Conveyors

THE PROBLEM

Fails to Deliver Rated Capacity Frequent Drive Motor Trips Conveyor Blockage Abnormal Wear on Drive Gears Excessive Shear Pin Breakage Excessive Bearing Failures/Wear

THE CAUSES Motor Overheats Excessive Noise

Blockage of Conveyor Ductwork

Chain Misaligned

Conveyor Chain Binding on Ductwork

Conveyor Not Emptied Before Shutdown

Conveyor Over-Filled When Idle

Excessive Looseness on Drive Chains

Excessive Moisture in Product

Foreign Object Obstructing Chain

Gear Set Center-to-Center Distance Incorrect

Gears Misaligned

Lack of Lubrication

Motor Speed Control Damaged or Not Calibrated

Product Density Too High

Too Much Volume/Load

Source: Integrated Systems, Inc.

filters are recommended for all applications, and controlled liquid injection for clean-

ing and cooling should be considered during the design process.

10.4.2 Rotary-Type Positive Displacement

Table 10–9 lists the common failure modes of rotary-type positive-displacement

compressors. This type of compressor can be grouped into two types: sliding vane

and rotary screw.

Sliding Vane

Sliding-vane compressors have the same failure modes as vane-type pumps. The dom-

inant components in their vibration profile are running speed, vane-pass frequency,

and bearing-rotation frequencies. In normal operation, the dominate energy is at the

shaft’s running speed. The other frequency components are at much lower energy