Page 241 - Intro Predictive Maintenance

P. 241

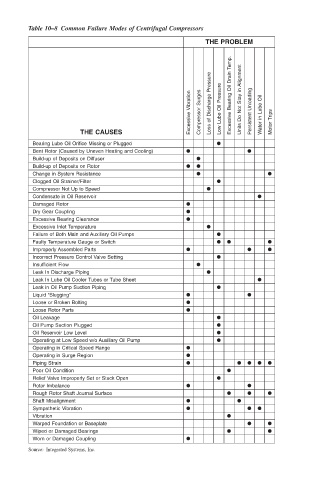

Table 10–8 Common Failure Modes of Centrifugal Compressors

THE PROBLEM

Excessive Vibration Compressor Surges Loss of Discharge Pressure Low Lube Oil Pressure Excessive Bearing Oil Drain Temp. Units Do Not Stay in Alignment Persistent Unloading Water in Lube Oil Motor Trips

THE CAUSES

Bearing Lube Oil Orifice Missing or Plugged

Bent Rotor (Caused by Uneven Heating and Cooling)

Build-up of Deposits on Diffuser

Build-up of Deposits on Rotor

Change in System Resistance

Clogged Oil Strainer/Filter

Compressor Not Up to Speed

Condensate in Oil Reservoir

Damaged Rotor

Dry Gear Coupling

Excessive Bearing Clearance

Excessive Inlet Temperature

Failure of Both Main and Auxiliary Oil Pumps

Faulty Temperature Gauge or Switch

Improperly Assembled Parts

Incorrect Pressure Control Valve Setting

Insufficient Flow

Leak In Discharge Piping

Leak In Lube Oil Cooler Tubes or Tube Sheet

Leak in Oil Pump Suction Piping

Liquid “Slugging”

Loose or Broken Bolting

Loose Rotor Parts

Oil Leakage

Oil Pump Suction Plugged

Oil Reservoir Low Level

Operating at Low Speed w/o Auxiliary Oil Pump

Operating in Critical Speed Range

Operating in Surge Region

Piping Strain

Poor Oil Condition

Relief Valve Improperly Set or Stuck Open

Rotor Imbalance

Rough Rotor Shaft Journal Surface

Shaft Misalignment

Sympathetic Vibration

Vibration

Warped Foundation or Baseplate

Wiped or Damaged Bearings

Worn or Damaged Coupling

Source: Integrated Systems, Inc.