Page 262 - Intro Predictive Maintenance

P. 262

Process Parameters 253

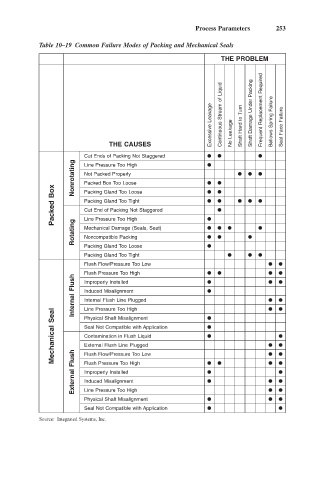

Table 10–19 Common Failure Modes of Packing and Mechanical Seals

THE PROBLEM

Excessive Leakage Continuous Stream of Liquid No Leakage Shaft Hard to Turn Shaft Damage Under Packing Frequent Replacement Required Bellows Spring Failure Seal Face Failure

THE CAUSES

Cut Ends of Packing Not Staggered

Nonrotating Not Packed Properly

Line Pressure Too High

Packed Box Too Loose

Packed Box Packing Gland Too Loose

Packing Gland Too Tight

Cut End of Packing Not Staggered

Line Pressure Too High

Rotating Mechanical Damage (Seals, Seat)

Noncompatible Packing

Packing Gland Too Loose

Packing Gland Too Tight

Flush Flow/Pressure Too Low

Flush Pressure Too High

Internal Flush Induced Misalignment

Improperly Installed

Internal Flush Line Plugged

Line Pressure Too High

Mechanical Seal Physical Shaft Misalignment

Seal Not Compatible with Application

Contamination in Flush Liquid

External Flush Line Plugged

External Flush Flush Pressure Too High

Flush Flow/Pressure Too Low

Improperly Installed

Induced Misalignment

Line Pressure Too High

Physical Shaft Misalignment

Seal Not Compatible with Application

Source: Integrated Systems, Inc.