Page 259 - Intro Predictive Maintenance

P. 259

250 An Introduction to Predictive Maintenance

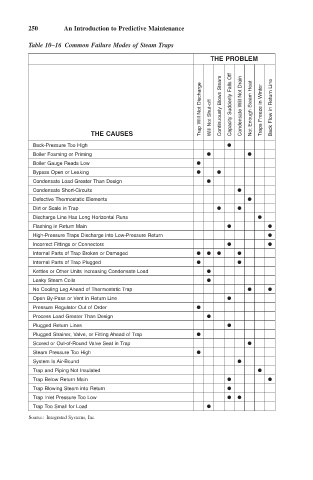

Table 10–16 Common Failure Modes of Steam Traps

THE PROBLEM

Trap Will Not Discharge Will Not Shut-off Continuously Blows Steam Capacity Suddenly Falls Off Condensate Will Not Drain Not Enough Steam Heat Traps Freeze in Winter Back Flow in Return Line

THE CAUSES

Back-Pressure Too High

Boiler Foaming or Priming

Boiler Gauge Reads Low

Bypass Open or Leaking

Condensate Load Greater Than Design

Condensate Short-Circuits

Defective Thermostatic Elements

Dirt or Scale in Trap

Discharge Line Has Long Horizontal Runs

Flashing in Return Main

High-Pressure Traps Discharge into Low-Pressure Return

Incorrect Fittings or Connectors

Internal Parts of Trap Broken or Damaged

Internal Parts of Trap Plugged

Kettles or Other Units Increasing Condensate Load

Leaky Steam Coils

No Cooling Leg Ahead of Thermostatic Trap

Open By-Pass or Vent in Return Line

Pressure Regulator Out of Order

Process Load Greater Than Design

Plugged Return Lines

Plugged Strainer, Valve, or Fitting Ahead of Trap

Scored or Out-of-Round Valve Seat in Trap

Steam Pressure Too High

System Is Air-Bound

Trap and Piping Not Insulated

Trap Below Return Main

Trap Blowing Steam into Return

Trap Inlet Pressure Too Low

Trap Too Small for Load

Source: Integrated Systems, Inc.