Page 255 - Intro Predictive Maintenance

P. 255

246 An Introduction to Predictive Maintenance

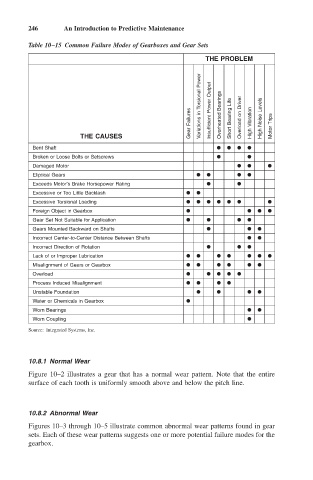

Table 10–15 Common Failure Modes of Gearboxes and Gear Sets

THE PROBLEM

Variations in Torsional Power Insufficient Power Output

Gear Failures Overheated Bearings Short Bearing Life Overload on Driver High Vibration High Noise Levels Motor Trips

THE CAUSES

Bent Shaft

Broken or Loose Bolts or Setscrews

Damaged Motor

Eliptical Gears

Exceeds Motor’s Brake Horsepower Rating

Excessive or Too Little Backlash

Excessive Torsional Loading

Foreign Object in Gearbox

Gear Set Not Suitable for Application

Gears Mounted Backward on Shafts

Incorrect Center-to-Center Distance Between Shafts

Incorrect Direction of Rotation

Lack of or Improper Lubrication

Misalignment of Gears or Gearbox

Overload

Process Induced Misalignment

Unstable Foundation

Water or Chemicals in Gearbox

Worn Bearings

Worn Coupling

Source: Integrated Systems, Inc.

10.8.1 Normal Wear

Figure 10–2 illustrates a gear that has a normal wear pattern. Note that the entire

surface of each tooth is uniformly smooth above and below the pitch line.

10.8.2 Abnormal Wear

Figures 10–3 through 10–5 illustrate common abnormal wear patterns found in gear

sets. Each of these wear patterns suggests one or more potential failure modes for the

gearbox.