Page 64 - Introduction to Computational Fluid Dynamics

P. 64

P1: IWV/ICD

0 521 85326 5

CB908/Date

0521853265c02

2.8 METHODS OF SOLUTION

Table 2.7: Solution by TDMA – Problem 2. May 25, 2005 10:49 43

x (cm) 0 0.2 0.6 1.0 1.4 1.8 2

A i − 0.333 0.598 0.711 0.772 0.0 −

B i − 149.78 89.628 63.776 49.357 212.375 −

l = 1 225 222.45 218.40 215.38 213.37 212.37 212.37

Exact 225 222.58 218.52 215.51 213.49 212.49 212.37

2

fin surface experiences heat transfer coefficient h = 20 W/m -K and the ambient

◦

temperature is T ∞ = 25 C. Assuming conduction to be radial, estimate the heat

loss from the fin and the fin effectiveness. Neglect heat loss from the fin tip.

Solution

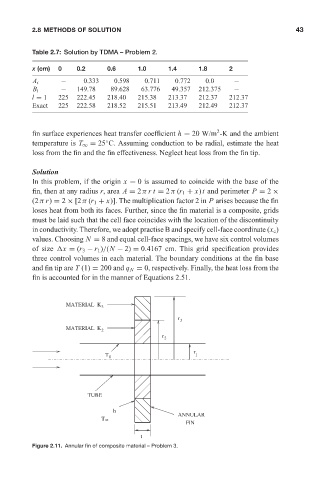

In this problem, if the origin x = 0 is assumed to coincide with the base of the

fin, then at any radius r, area A = 2π rt = 2π (r 1 + x)t and perimeter P = 2 ×

(2π r) = 2 × [2π (r 1 + x)]. The multiplication factor 2 in P arises because the fin

loses heat from both its faces. Further, since the fin material is a composite, grids

must be laid such that the cell face coincides with the location of the discontinuity

in conductivity. Therefore, we adopt practise B and specify cell-face coordinate (x c )

values. Choosing N = 8 and equal cell-face spacings, we have six control volumes

of size x = (r 3 − r 1 )/(N − 2) = 0.4167 cm. This grid specification provides

three control volumes in each material. The boundary conditions at the fin base

and fin tip are T (1) = 200 and q N = 0, respectively. Finally, the heat loss from the

fin is accounted for in the manner of Equations 2.51.

MATERIAL K 3

r 3

MATERIAL K

2

r 2

r

T 0 1

TUBE

h

ANNULAR

Τ 8

FIN

t

Figure 2.11. Annular fin of composite material – Problem 3.