Page 321 - Introduction to Information Optics

P. 321

306 6. Interconnection with Optics

tion technologies. The experimental results indicate that high-performance

polymeric waveguide circuits with waveguide propagation loss less than 0,02

dB/cm can be produced by using laser-writing technique. Compression-mold-

ing technique has demonstrated its uniqueness in producing three-dimensional

(3D) tapered waveguide circuits, crucial for obtaining efficient optical coupling

between the input laser diode and the waveguide circuit. Mass-producible

waveguides with excellent repetitiveness have been obtained by using VLSI

lithography technique, originally developed for fabricating very large scale

integrated circuits on silicon wafers,

6.2.2.1. Compression-Molding Technique

High-performance polymeric waveguides can be obtained at low cost with

compression-molding technique. The process of compression molding is

described by reference to Fig. 6.2. A two-piece mold provides a cavity having

the shape of the target polymer-based channel waveguide array. The mold is

heated to a desired temperature that is often above the glass transition

temperature. An appropriate amount of molding material, polymer waveguide

film in this case, is loaded into the substrate. The molding process is conducted

by bringing two parts of the mold together under pressure. The polymer film,

softened by heat, is thereby welded into the shape of the stamp. The molding

process is performed during the phase-transition period within which the

polymer film is deformable. The compression-molding technique has produced

polymeric waveguides with shape and sizes typically unachievable by other

methods.

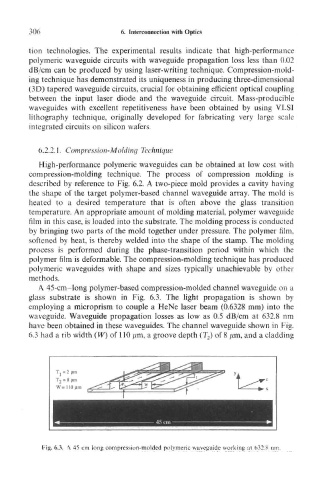

A 45-cm-long polymer-based compression-molded channel waveguide on a

glass substrate is shown in Fig. 6.3. The light propagation is shown by

employing a microprism to couple a HeNe laser beam (0.6328 mm) into the

waveguide. Waveguide propagation losses as low as 0.5 dB/cm at 632.8 nm

have been obtained in these waveguides. The channel waveguide shown in Fig.

6.3 had a rib width (W) of 110 /im, a groove depth (T 2) of 8 /mi, and a cladding

Fig. 6.3. A 45 cm long compression-molded polymeric waveguide working at 632.8 nm.